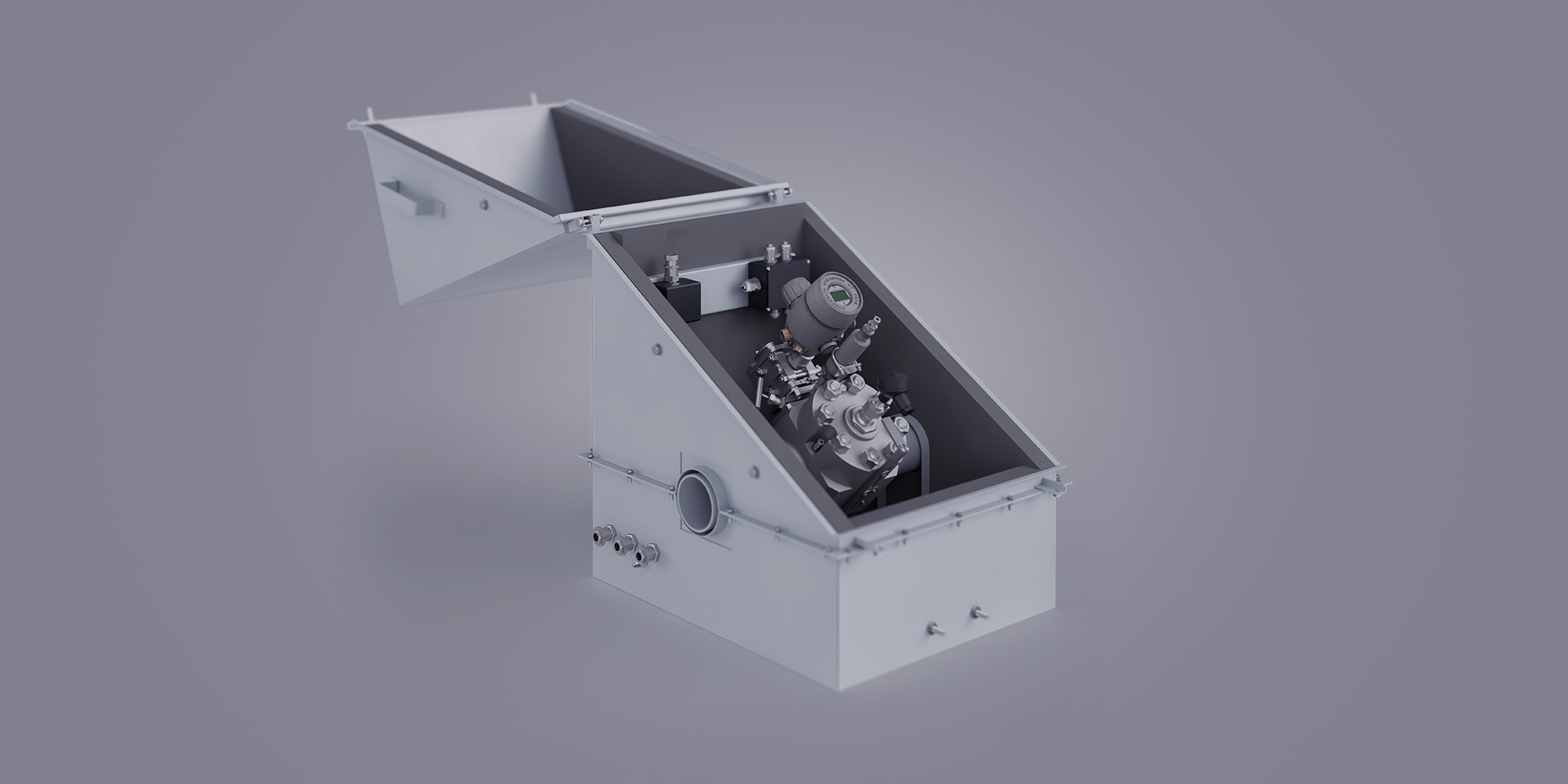

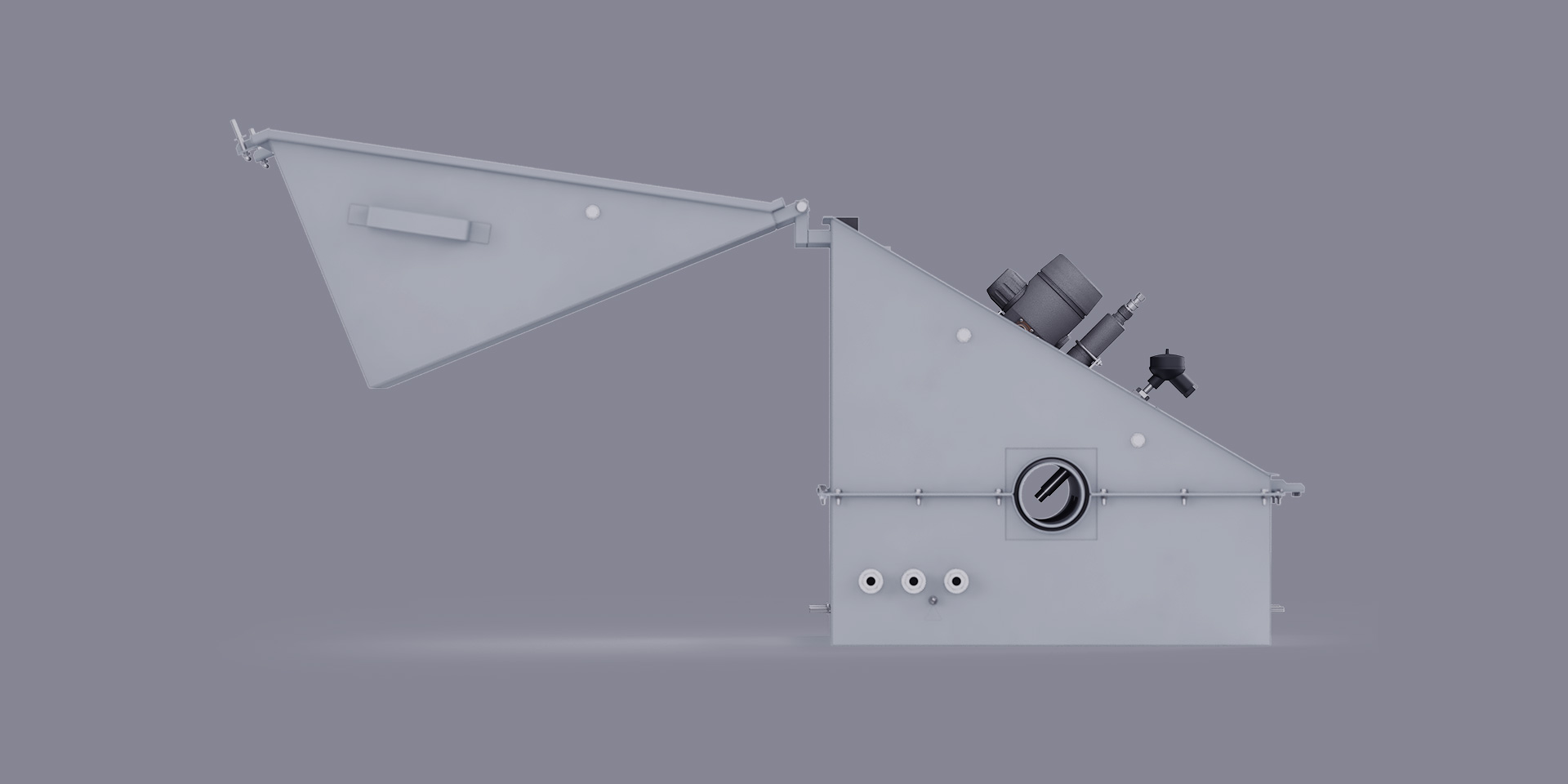

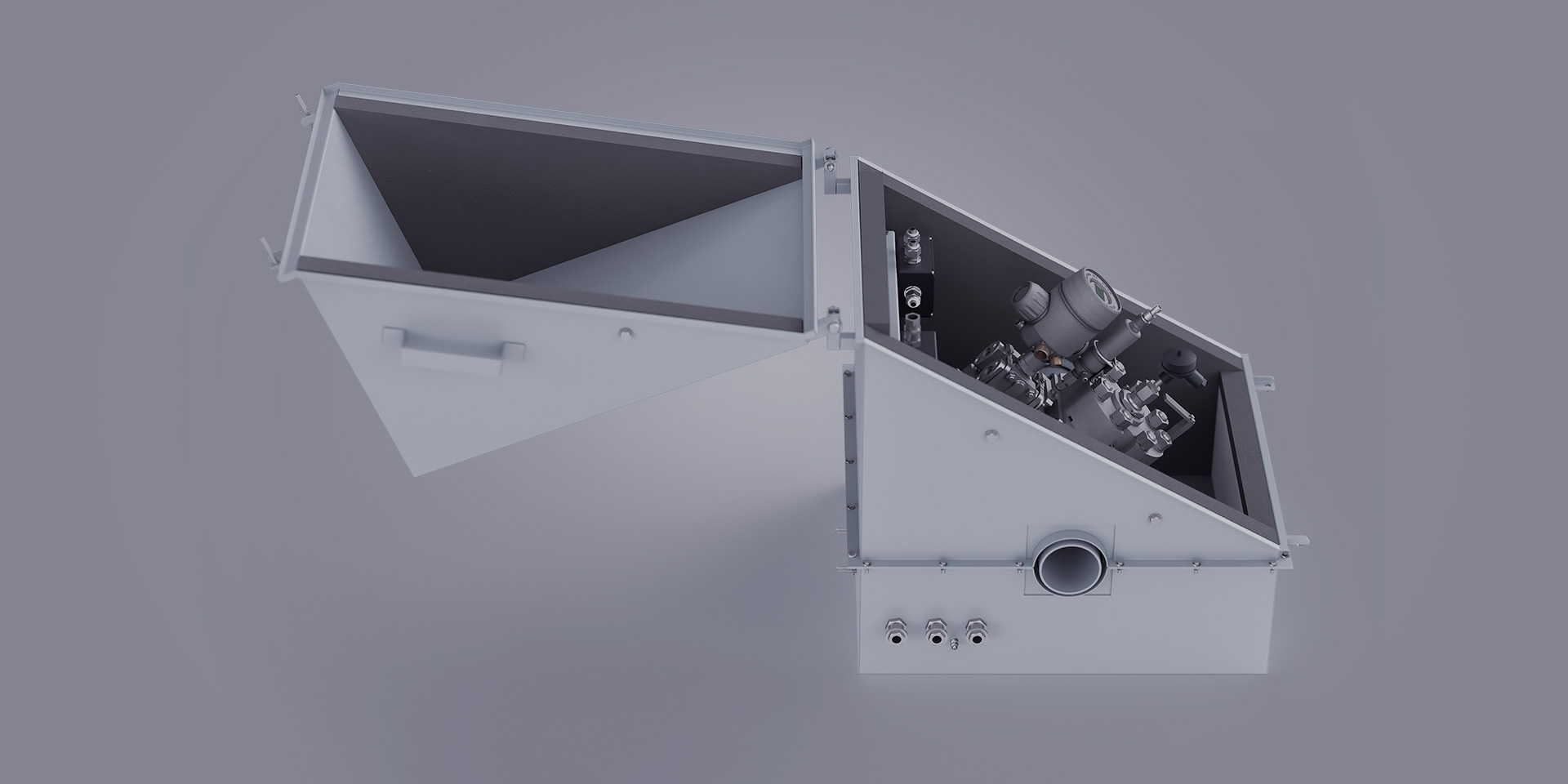

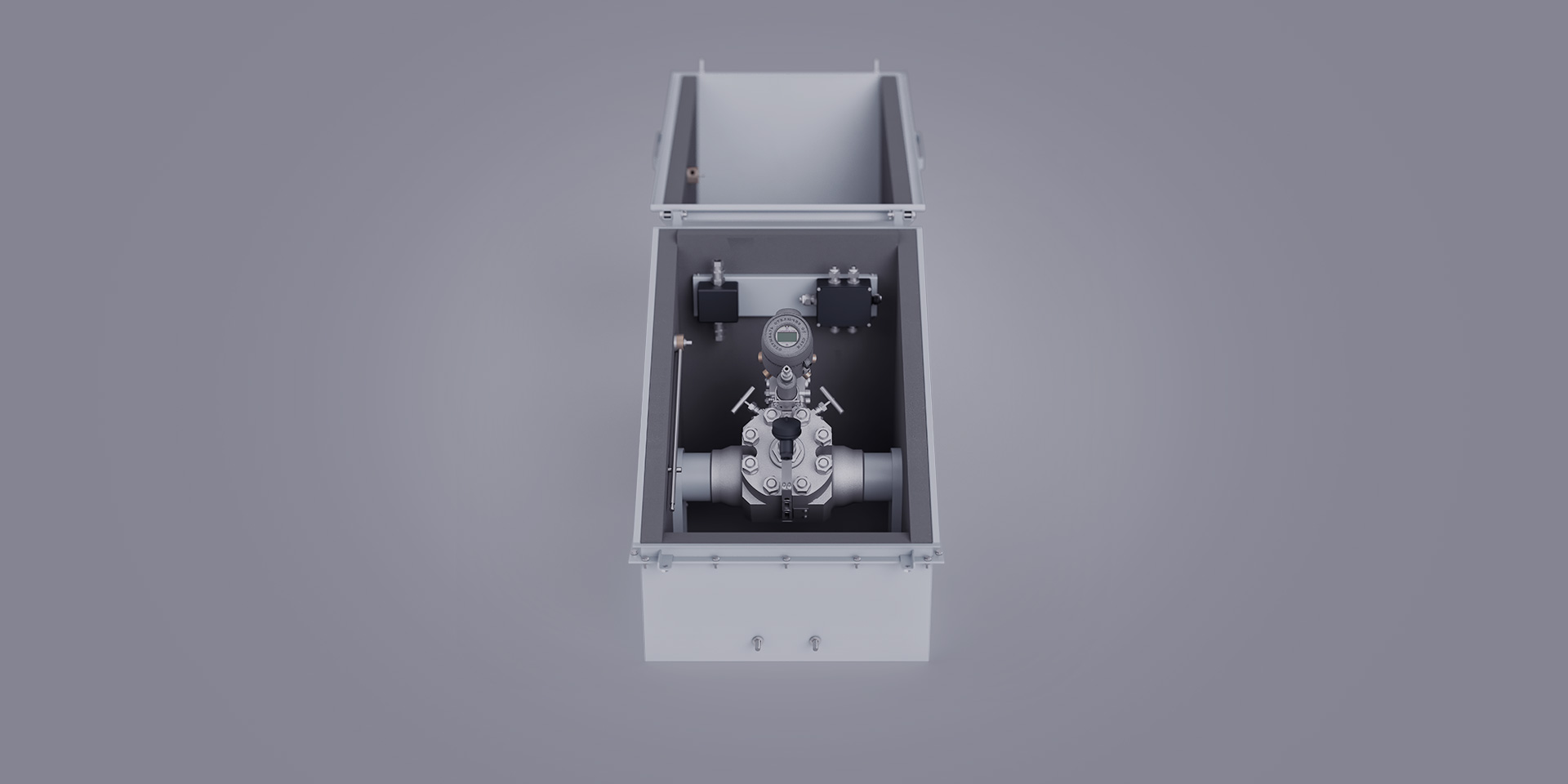

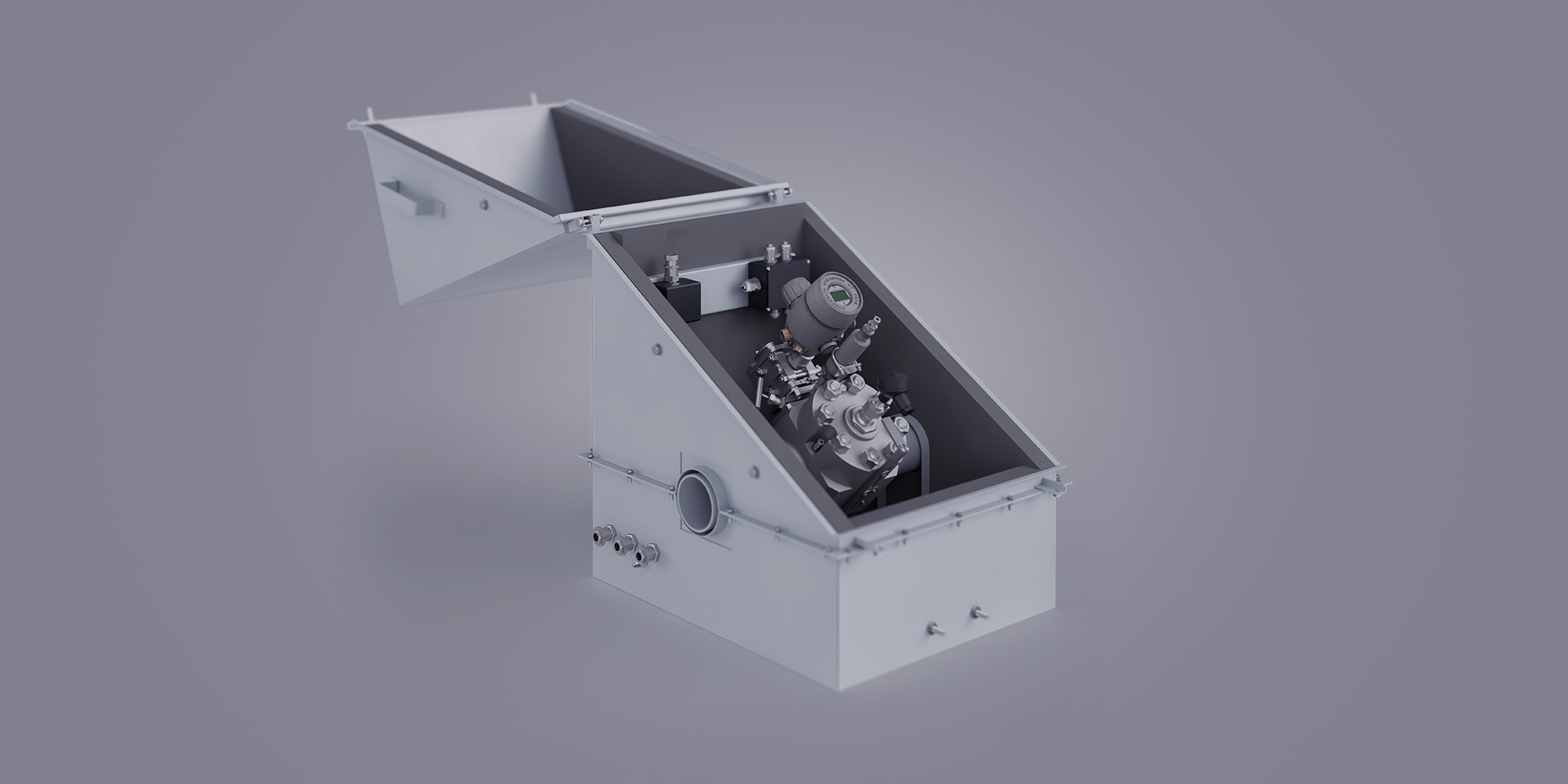

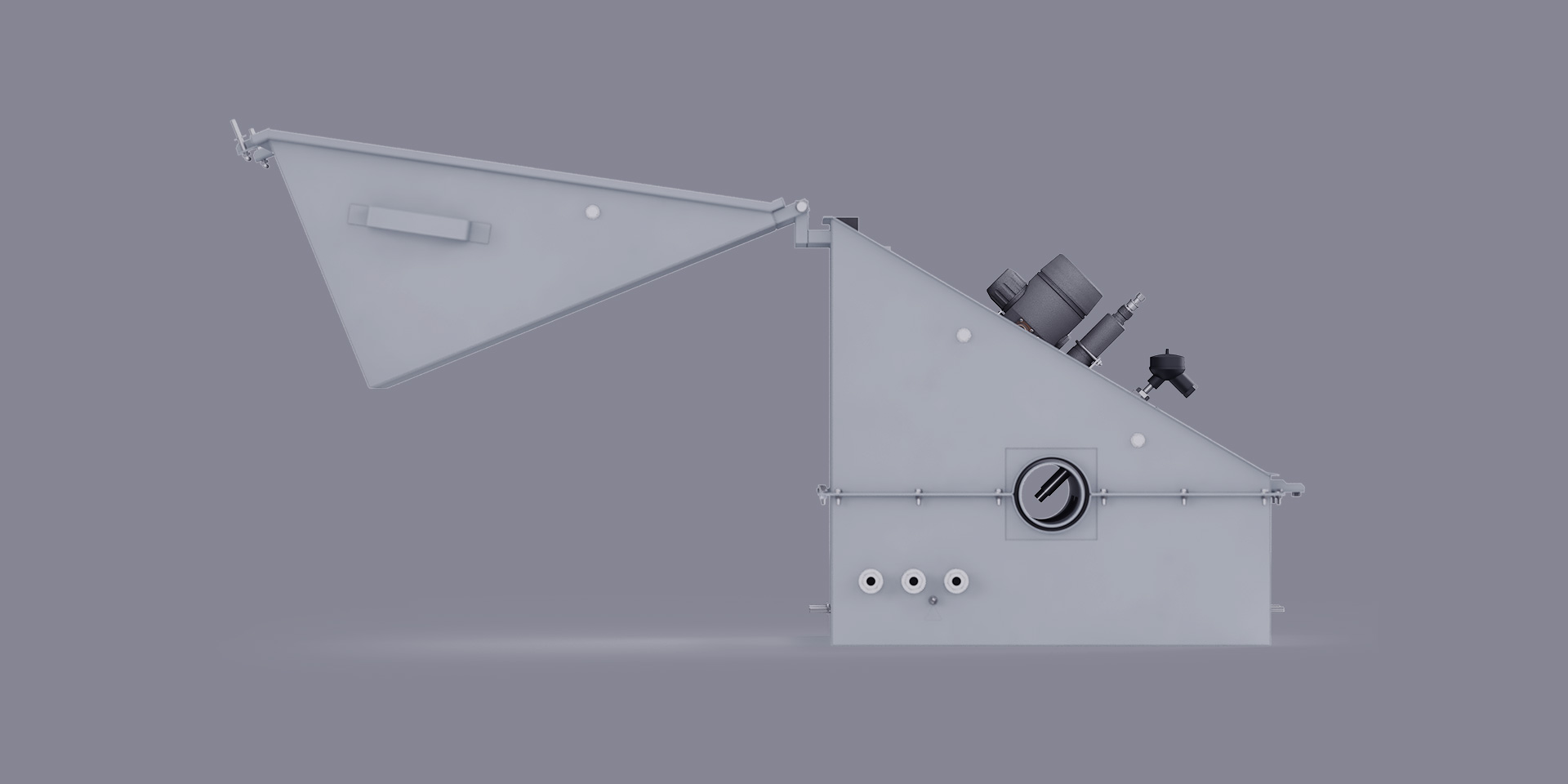

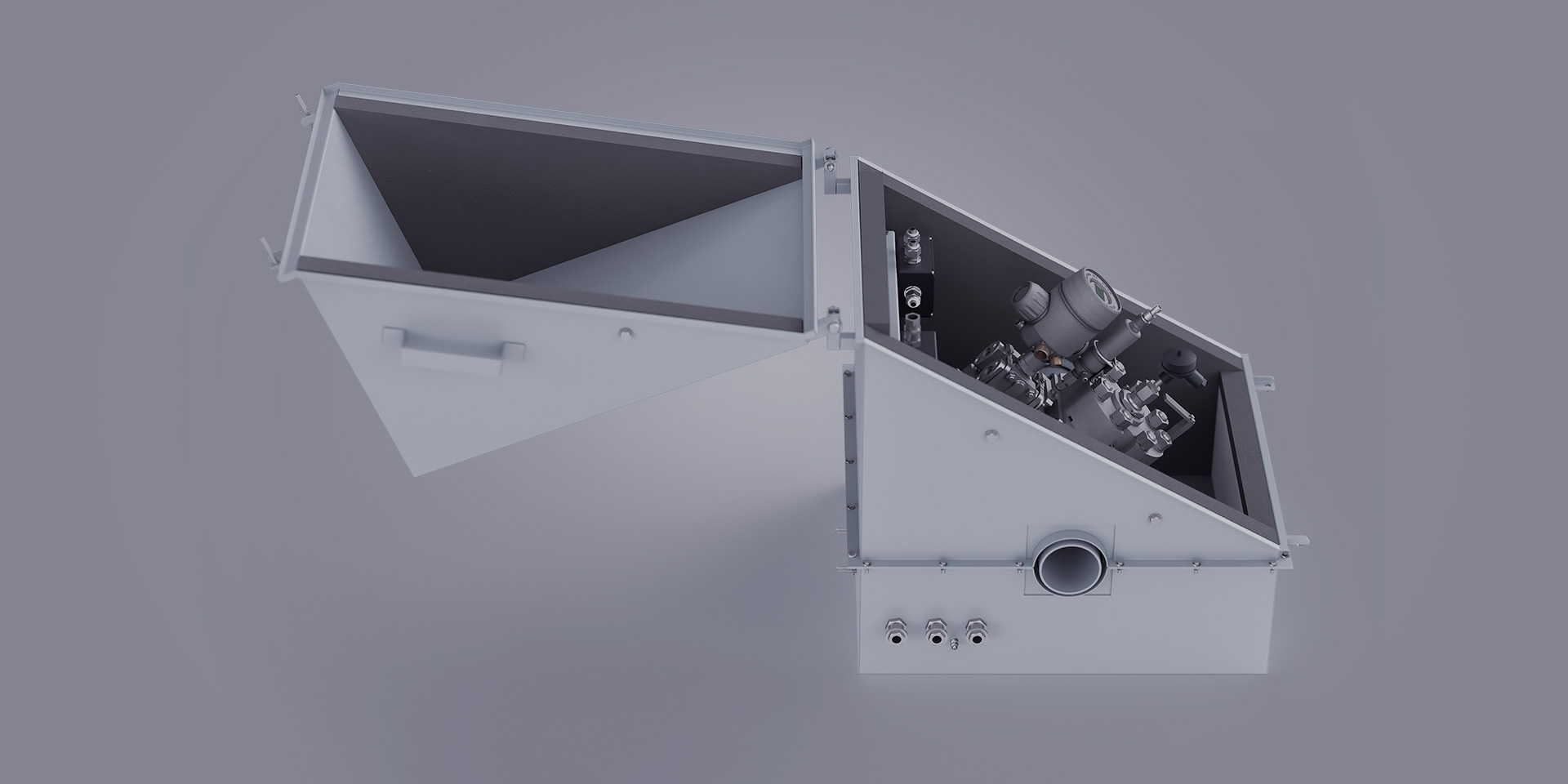

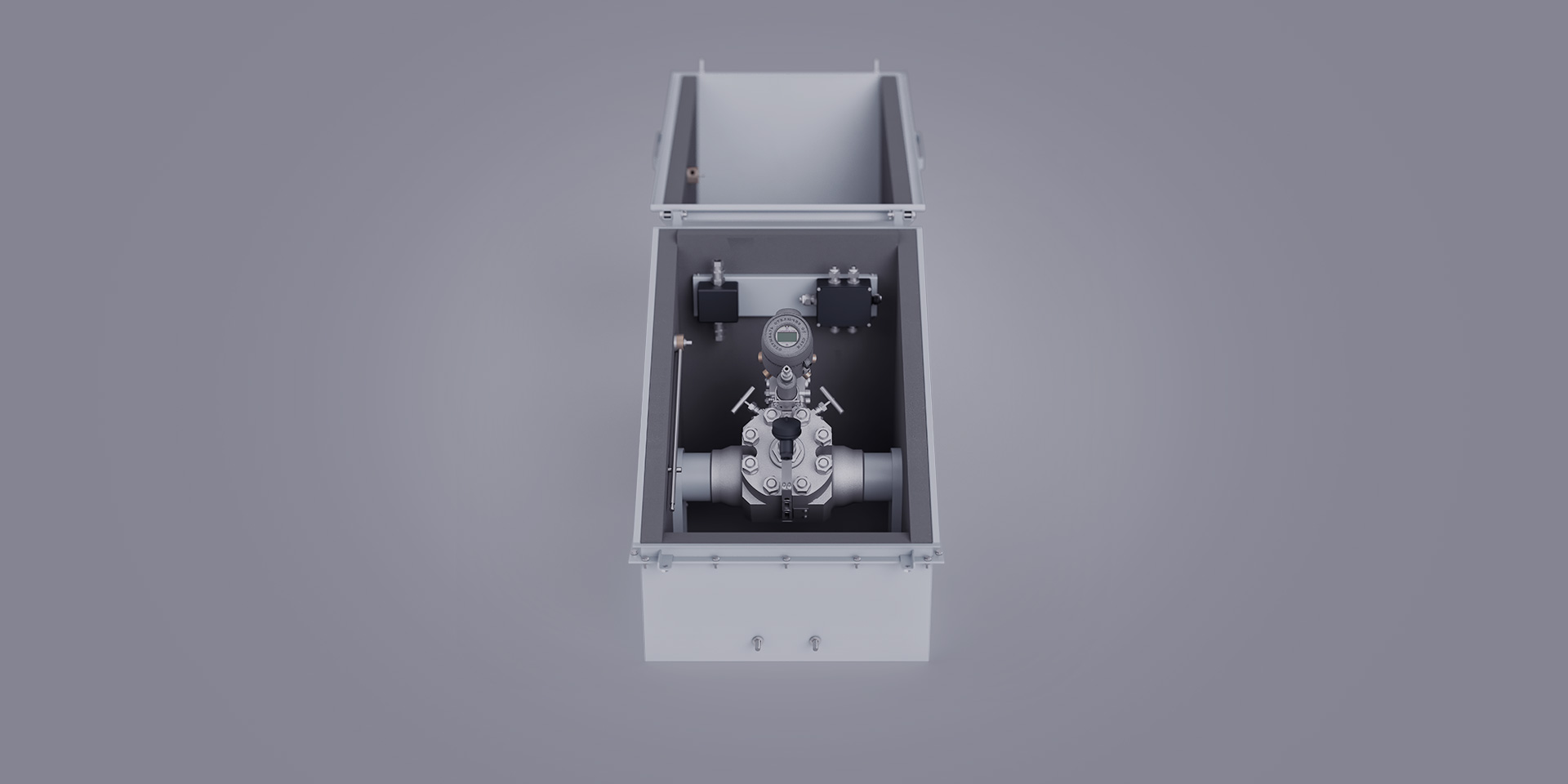

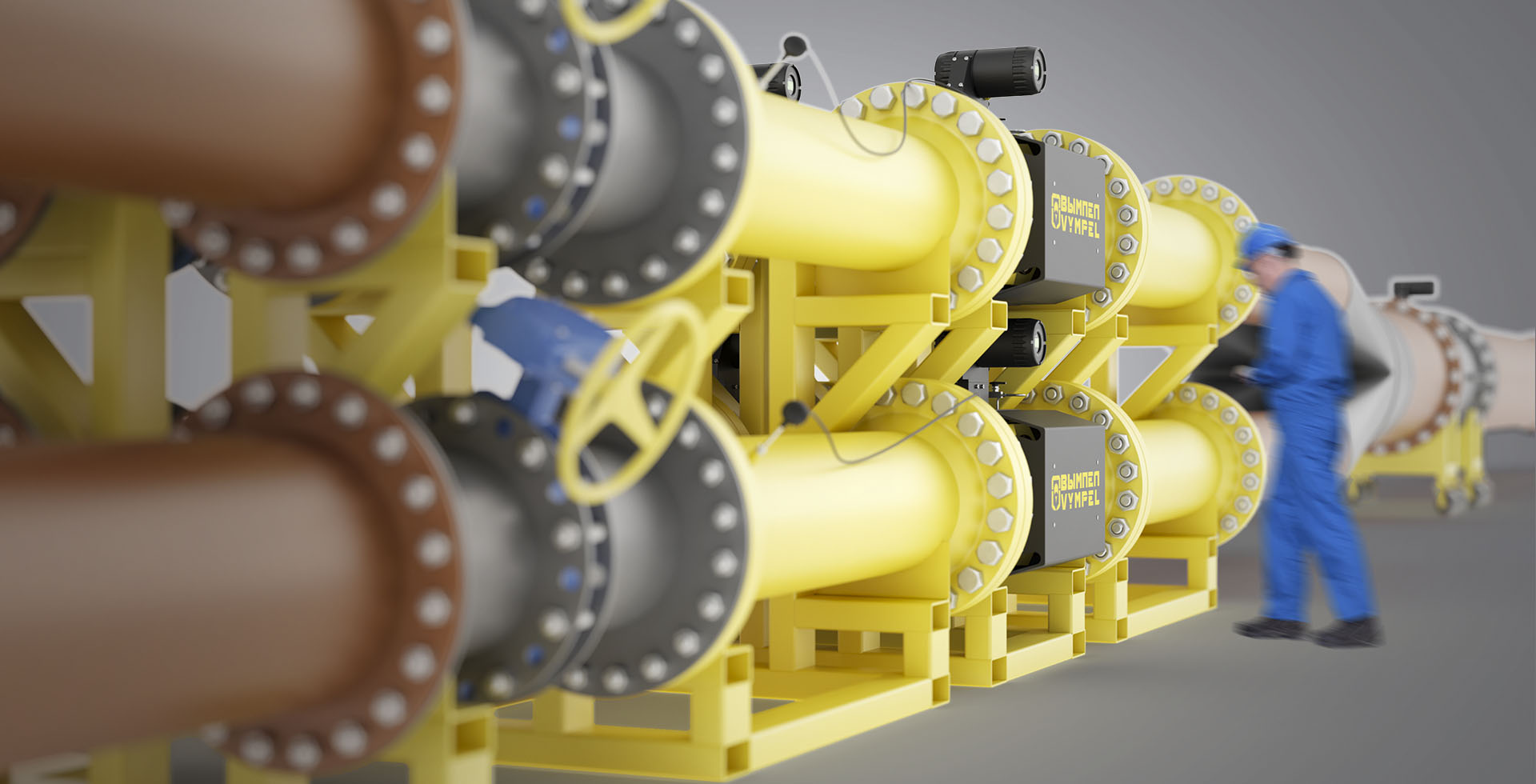

HyperFlow

downhole flowmeter

This HyperFlow gas flowmeter is designed for measuring the flow of natural gas adjusted to standard conditions at gas production sites, storage and transportation facilities. It can measure in direct and reverse flow as a self-contained metering device and as part of an automated accounting and control system or for data transmission to other systems. These flowmeters are designed for installation on pipelines with nominal diameters of DN100 and DN150. The flow measurement range is 400 to 350,000 Sm3/h, at working pressure of up to 16.0 MPa; or 25.0 MPa.

The flowmeter is installed complete with a cover and a heat insulator for ingress protection. To inhibit hydrate formation, the flowmeter includes a temperature stabilization unit BTS-003.

HyperFlow gas flowmeters are designed for use in explosion hazardous areas in accordance with the types of explosion protection of individual components, which bear the markings «1ExibIIAT5X» and «2ExmIIT5X» respectively.

Application fields

- production wells

- underground gas storage (UGS) wells

Signature

features

Characteristics

0.16…16.0 (1.6…160 kg/cm2)

Measuring principle:

Questionnaire

Configuration*

Operating manuals

Certificates

Product order

Vympel-80000

Grade 1 gas volume flow rate standard in value range of 800...80000 m3/h