Production

Production and implementation of unique innovative designs based on laser, ultrasonic and fiber-optic technologies.

General Information

SPA Vympel

creates and produces fully automated non-volatile information management

systems for natural gas recovery, transportation and distribution.

For 30 years we have been working in

three main areas:

Automation of pipeline stations using renewable energy as a power source

Gas quality monitoring;

Gas flow measurement.

Enterprise capabilities

Thanks to our highly trained specialists, modern machinery and equipment, and many years of production experience we can perform the necessary technological operations for the manufacture and delivery of effective solutions that function reliably in difficult operating conditions.

The company has implemented the

quality management system in accordance with the requirements of the standard

GOST ISO 9001 2011

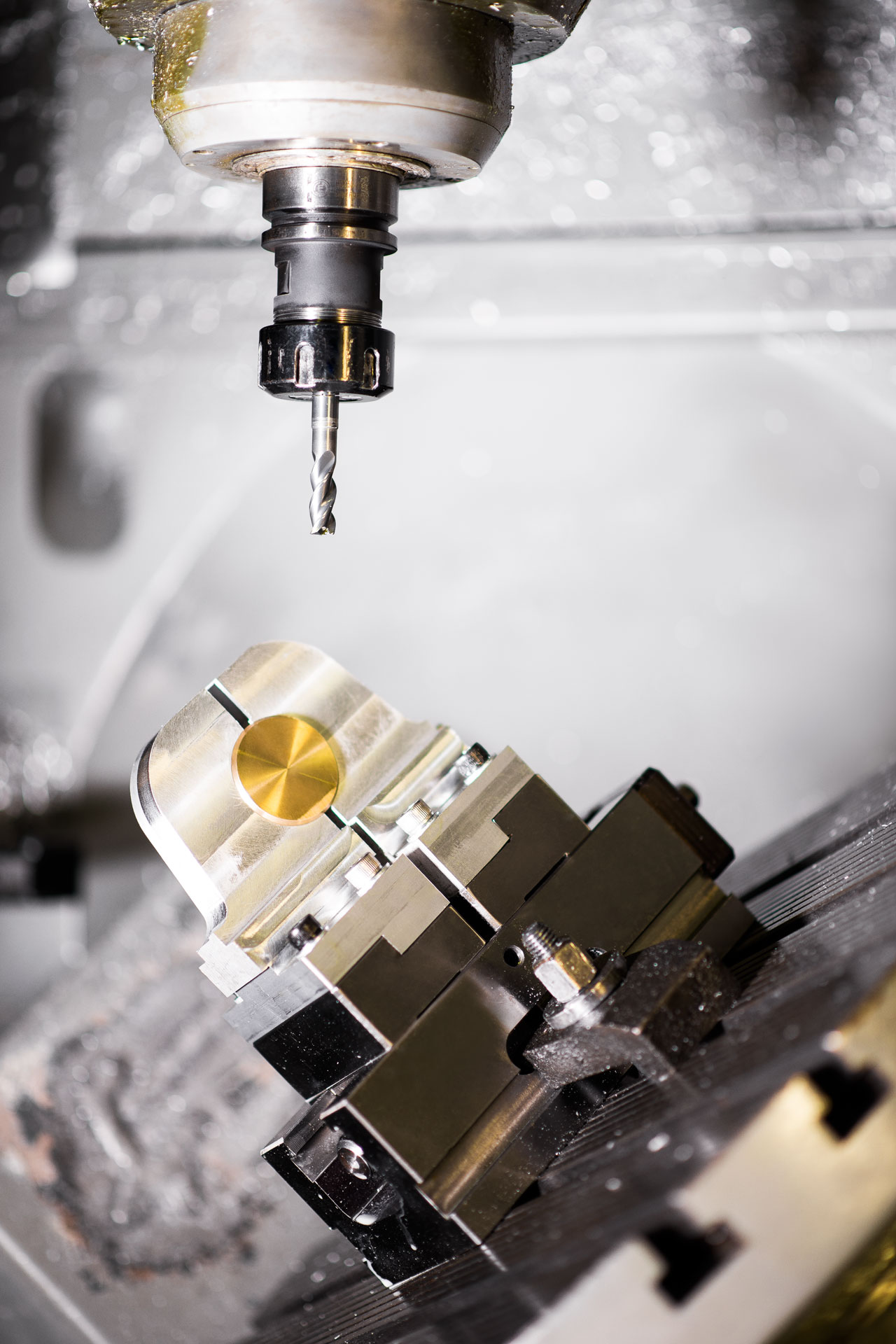

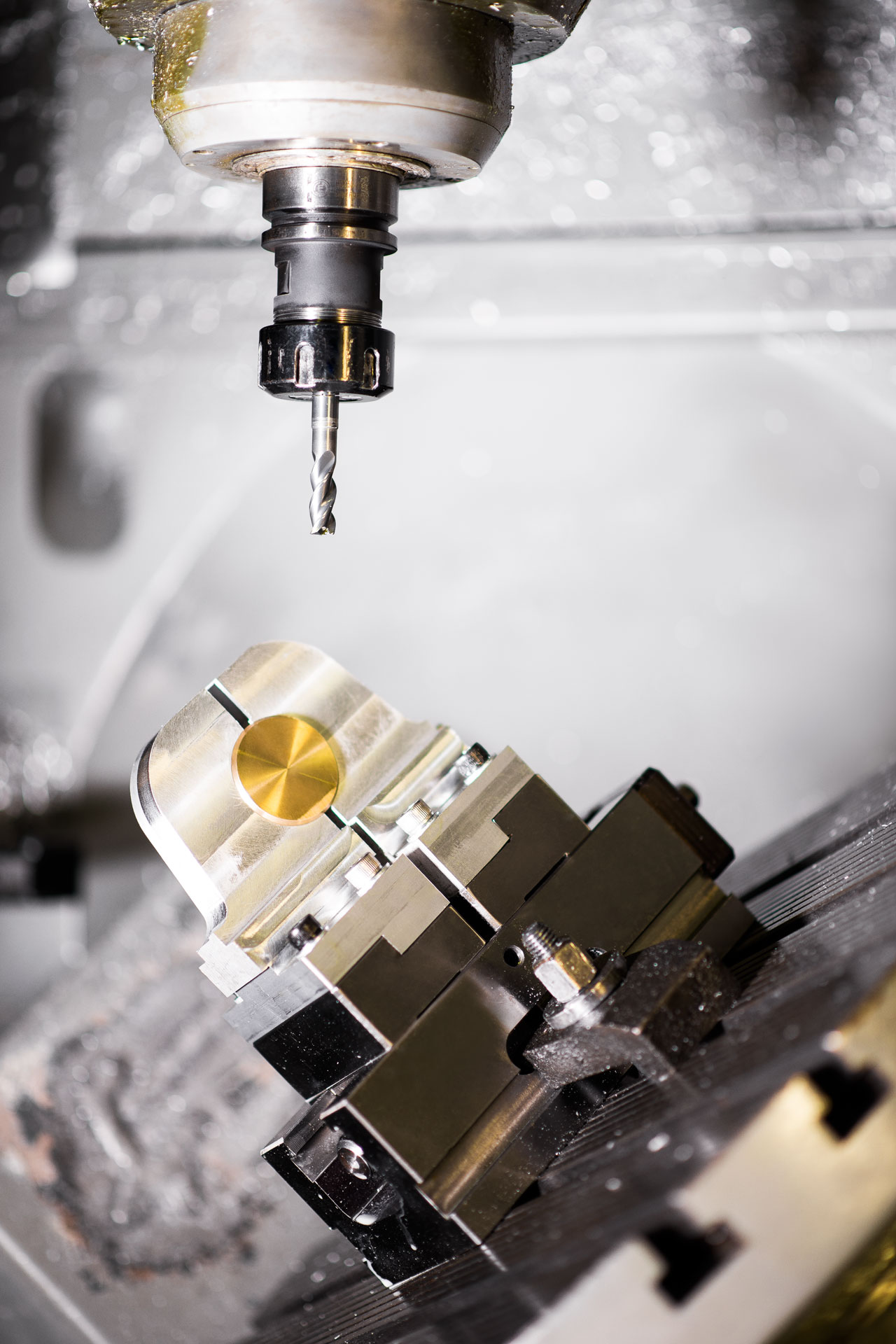

Machining

Machining is performed using modern high-precision and high-performance equipment:

01

DECKEL-MANO milling machining

centers

02

GILDEMEISTER, SPINNER,

SCHAUBLINMACHINESSA CNC Lathes

03

GRS105 CNC horizontal boring

machine with turn table and others

Processed materials

- aluminum alloys;

- stainless alloys;

- brass and bronze alloys;

- nonmetals: :

- caprolon;

- fluorine and others.

Welding is performed using a robotic technological complex based on the KUKA KR 60 L30-3 German industrial robot and KemppiKempArcPulse 450 welding equipment

The company has equipment on-site capable of boring pipe that is up to 1000 mm in diameter and up to 5 meters in length.

Assembly and installation

Assembly and installation include:

01

Circuit board surface mounting technology

(automated production line equipped with an SMD component installation machine by YAMAHA MOTOR CO, LTD [i-PULSE Business Division] and the ESSEMTEC convection reflow oven);

02

Manual assembly of complex special-purpose components;

03

Cleaning of electronic products;

04

Application of waterproof coatings

and compounding;

05

Manufacture of cables;

06

Package assembly of units and

cabinets.

Products are tested on automatic test benches and in TABAI and TERCHY climatic cells.

Product quality is monitored continuously at all stages of a product’s life cycle.

Production process automation, the implementation of new technologies, modern high-tech equipment and the high-level of qualification of the specialists working at all of our sites ensure consistently high product quality.

Production

photos

Product testing

The products are tested on automatic test benches and in TABAI and TERCHY climatic cells.

Modern equipment

The company has a stock of equipment that allows pipe boring up to 1000 mm in diameter and up to 5 meters in length.

Highly qualified personnel

The company has a highly qualified staff of engineering and technical workers and workers.

Modern high-precision and high-performance machining equipment

- DECKEL-MANO milling machining centers

- GILDEMEISTER, SPINNER, SCHAUBLINMACHINESSA CNC Lathes

- GRS105 CNC horizontal boring machine with turn table and others

Assembly and installation

Wide range of processed materials

Processed materials: aluminum alloys, stainless alloys, brass and bronze alloys, nonmetals (caprolon, fluorine and others).

Product testing

The products are tested on automatic test benches and in TABAI and TERCHY climatic cells.

Modern equipment

The company has a stock of equipment that allows pipe boring up to 1000 mm in diameter and up to 5 meters in length.

Highly qualified personnel

The company has a highly qualified staff of engineering and technical workers and workers.

Modern high-precision and high-performance machining equipment

- DECKEL-MANO milling machining centers

- GILDEMEISTER, SPINNER, SCHAUBLINMACHINESSA CNC Lathes

- GRS105 CNC horizontal boring machine with turn table and others

Assembly and installation

Wide range of processed materials

Processed materials: aluminum alloys, stainless alloys, brass and bronze alloys, nonmetals (caprolon, fluorine and others).

Use the keyboard