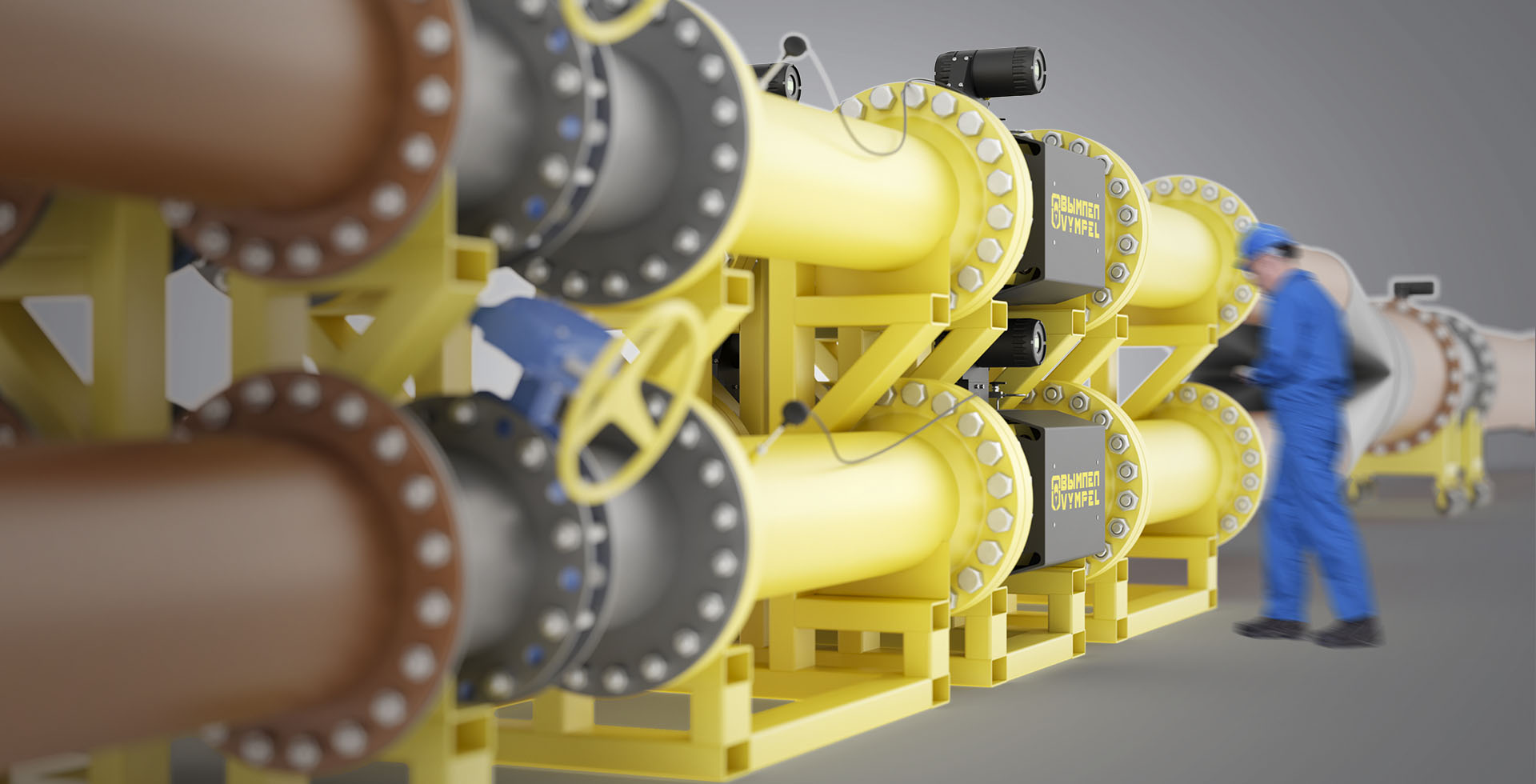

Flowmeters

From production sites to end users

SPA Vympel produces a line of flowmeters designed for the specific requirements of a wide range of the gas industry tasks: from production sites to end users.

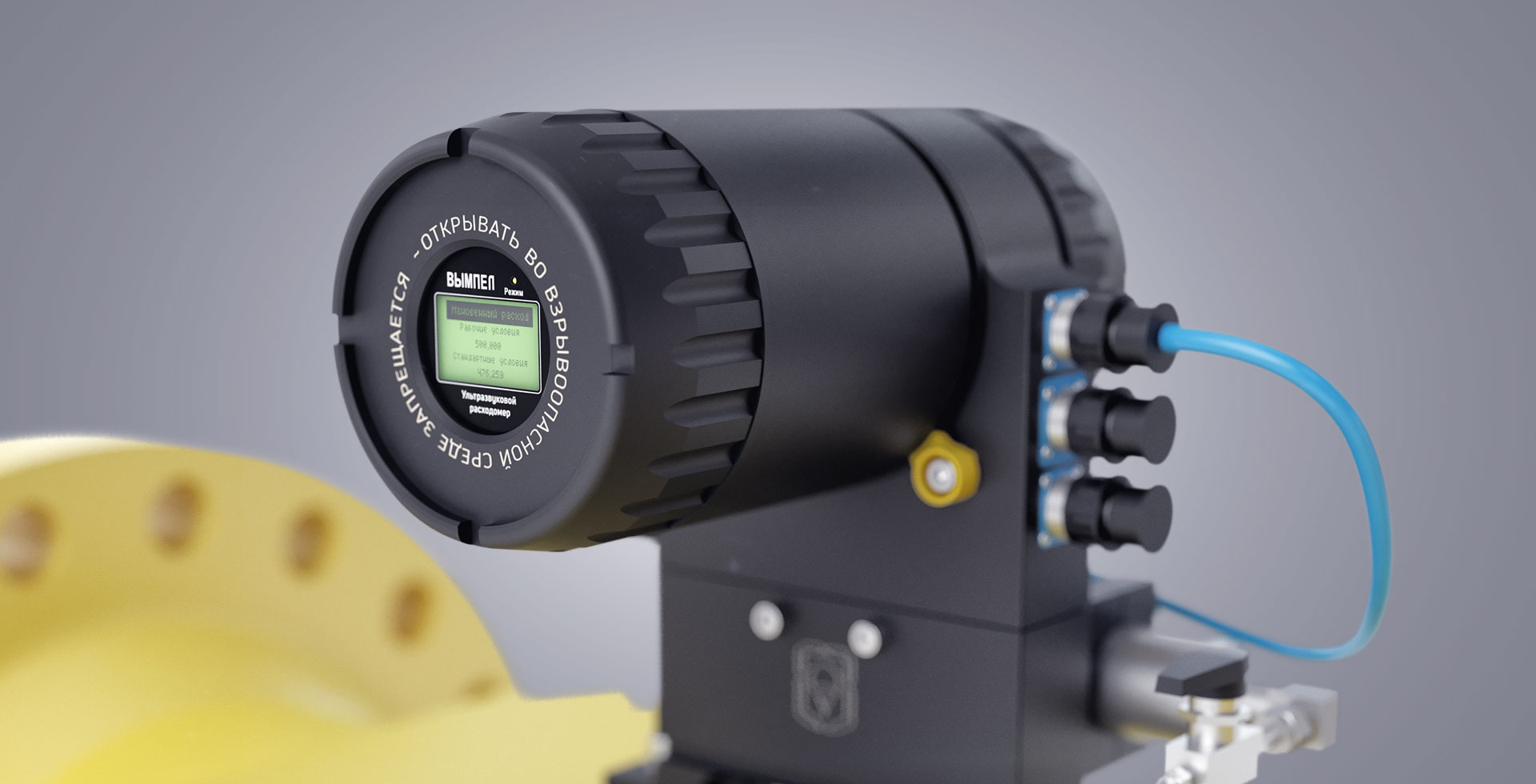

VYMPEL-500

Multibeam ultrasonic measuring system

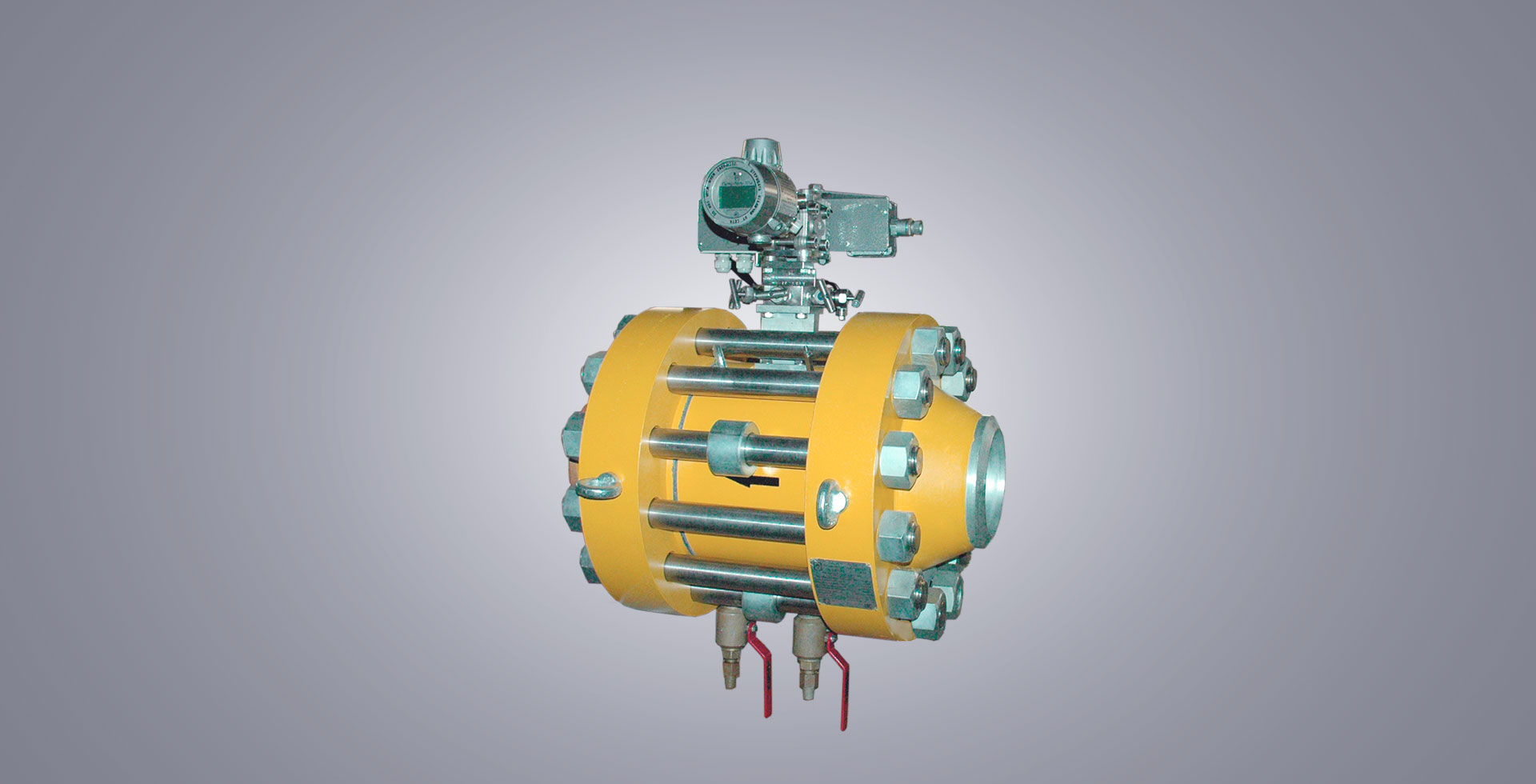

HyperFlow-3Pm

HyperFlow-3Pm complex sensor with a flow calculation unit

HyperFlow-ISA gas flow meter

Снято с производства

The flowmeter based on the standard constriction device: ISA 1932 nozzle

HyperFlow downhole flowmeter

Flowmeter based on a non-standard constriction device

Vympel-80000

Grade 1 gas volume flow rate standard in value range of 800...80000 m3/h

OIML R 137

Meet the

requirements of the International Organization of Legal Metrology

Сравнение моделей Расходометров

Метод измерения

Ультразвуковой 2,4,8-канальный, «датчик в датчик»

Ультразвуковой, двухканальный с фокусирующей пластиной

Ультразвуковой, 4-канальный, с отражениями

Метод переменного перепада давления

Метод переменного перепада давления

Метод переменного перепада давления

Ультразвуковой 2,4,8-канальный, «датчик в датчик»

Ультразвуковой, двухканальный с фокусирующей пластиной

Ультразвуковой, 4-канальный, с отражениями

Метод переменного перепада давления

Метод переменного перепада давления

Метод переменного перепада давления

Область применения

Коммерческие узлы учета газа

Газораспределительные станции, ТЭЦ, котельные, жилые дома, топливные газы

Технологический учет на трубопроводах большого диаметра

Скважины добычи природного газа и ПХГ

Скважины добычи природного газа ПХГ

Коммерческие и промышленные узлы учета расхода природного газа, воды, пара, других жидких и газообразных сред;

Скважины добычи, хранения газа;

Скважины добычи газового конденсата в составе двухфазных расходомеров ДФР-01;

Системы телемеханики «ГиперФлоу-ТМ» в качестве узлов измерения давления и температуры;

Системы одорирования газа для измерения расхода одоранта; Системы измерения расхода сжиженного природного газа

Коммерческие узлы учета газа

Газораспределительные станции, ТЭЦ, котельные, жилые дома, топливные газы

Технологический учет на трубопроводах большого диаметра

Скважины добычи природного газа и ПХГ

Скважины добычи природного газа ПХГ

Коммерческие и промышленные узлы учета расхода природного газа, воды, пара, других жидких и газообразных сред;

Скважины добычи, хранения газа;

Скважины добычи газового конденсата в составе двухфазных расходомеров ДФР-01;

Системы телемеханики «ГиперФлоу-ТМ» в качестве узлов измерения давления и температуры;

Системы одорирования газа для измерения расхода одоранта; Системы измерения расхода сжиженного природного газа

Особенности

Повышенная точность измерения;

Повышенная акустическая и электромагнитная помехоустойчивость;

Замена преобразователей без остановки процесса;

Возможность проведения поверки имитационным способом

Компактность;

Отсутствие прямых участков;

Расширенный диапазон измерения

Возможность врезки в трубопровод без сброса давления;

Возможность поверки на объекте имитационным способом

Повышенная износостойкость за счет профиля сопла, который не имеет острых выступающих частей

Измерение неподготовленного природного газа в широком диапазоне рабочих температур от - 60 до + 60 °С;

Изменение диапазона измерения без остановки процесса

Высокая точность измерения в диапазоне рабочих температур от — 60 до + 60° С.

Возможность снятия зависимости выходных сигналов от задаваемых образцовых значений

Повышенная точность измерения;

Повышенная акустическая и электромагнитная помехоустойчивость;

Замена преобразователей без остановки процесса;

Возможность проведения поверки имитационным способом

Компактность;

Отсутствие прямых участков;

Расширенный диапазон измерения

Возможность врезки в трубопровод без сброса давления;

Возможность поверки на объекте имитационным способом

Повышенная износостойкость за счет профиля сопла, который не имеет острых выступающих частей

Измерение неподготовленного природного газа в широком диапазоне рабочих температур от - 60 до + 60 °С;

Изменение диапазона измерения без остановки процесса

Высокая точность измерения в диапазоне рабочих температур от — 60 до + 60° С.

Возможность снятия зависимости выходных сигналов от задаваемых образцовых значений

Измеряемая среда

Природный газ и др. газовые среды

Природный газ и др. газовые среды

Природный газ и др. газовые среды

Газы, в том числе природный газ

Газы, в том числе природный газ

Газы, в том числе природный газ; жидкости, в том числе вода

Природный газ и др. газовые среды

Природный газ и др. газовые среды

Природный газ и др. газовые среды

Газы, в том числе природный газ

Газы, в том числе природный газ

Газы, в том числе природный газ; жидкости, в том числе вода

Диапазон измеряемых расходов

200:1

500:1

100:1

10:1

30:1 с дополнительным датчиком перепада давления

10:1 без изменения положения штока

40:1 с изменением положения штока

10:1

30:1 с дополнительным датчиком перепада давления

200:1

500:1

100:1

10:1

30:1 с дополнительным датчиком перепада давления

10:1 без изменения положения штока

40:1 с изменением положения штока

10:1

30:1 с дополнительным датчиком перепада давления

Интервал между поверками

4 года

4 года

4 года

1, 2 или 3 года, в зависимости от точности

1 год / 3 года в зависимости от точности

1, 2 или 3 года, в зависимости от точности

4 года

4 года

4 года

1, 2 или 3 года, в зависимости от точности

1 год / 3 года в зависимости от точности

1, 2 или 3 года, в зависимости от точности

Номинальные диаметры

DN 50-DN 1400

DN 50-DN 100

DN 100-DN 1600

DN100, DN150, DN200, DN250, DN300

DN 100; DN 150

50 … 3000 мм

DN 50-DN 1400

DN 50-DN 100

DN 100-DN 1600

DN100, DN150, DN200, DN250, DN300

DN 100; DN 150

50 … 3000 мм

Рабочее давление

0,1-25 МПа

0,1-10 МПа

0,1-16 МПа

25 МПа

16, 25 МПа

0.6 … 60 МПа

0,1-25 МПа

0,1-10 МПа

0,1-16 МПа

25 МПа

16, 25 МПа

0.6 … 60 МПа

Параметры взрывозащиты

Exd[ibllC]IIAT6Gb

1Ex[ib]ibIIAT5

1Ex[ib]IIAT6 Х

1Ex ib IIВ T5 Gb Х,

1Ex mb IIB T5 Gb X для БТС-003

1Ex ib IIВ T5 Gb Х,

1Ex mb IIB T5 Gb X для БТС-003

1Ex ib IIВ T5 Gb Х

Exd[ibllC]IIAT6Gb

1Ex[ib]ibIIAT5

1Ex[ib]IIAT6 Х

1Ex ib IIВ T5 Gb Х,

1Ex mb IIB T5 Gb X для БТС-003

1Ex ib IIВ T5 Gb Х,

1Ex mb IIB T5 Gb X для БТС-003

1Ex ib IIВ T5 Gb Х

Рабочие скорости

0,15-35 м/c

0,06-30 м/с

0,3 - 30 м/с

До 40 м/c

до 60 м/с

0,15-35 м/c

0,06-30 м/с

0,3 - 30 м/с

До 40 м/c

до 60 м/с

Допускаемая относительная погрешность измерения расхода

0,3%; 0,5%; 0,7%;1,0%;1,5%

1,0%

1,25%; 1,5%; 2 %

0,01

± 2,5 %

±4,0 %

Параметр не нормируется

0,3%; 0,5%; 0,7%;1,0%;1,5%

1,0%

1,25%; 1,5%; 2 %

0,01

± 2,5 %

±4,0 %

Параметр не нормируется

Питание

24В / ≤4 Вт

14-28В/≤4Вт, автономное питание до 2х лет

14-28В/ ≤1,5 Вт, автономное питание до 2-х лет

10-30В / ≤4 Вт, автономное питание до 5 лет

10-30 В/≤4 Вт, автономное, встроенное питание до 5 лет

10-30В / ≤4 Вт, автономное питание до 5 лет

24В / ≤4 Вт

14-28В/≤4Вт, автономное питание до 2х лет

14-28В/ ≤1,5 Вт, автономное питание до 2-х лет

10-30В / ≤4 Вт, автономное питание до 5 лет

10-30 В/≤4 Вт, автономное, встроенное питание до 5 лет

10-30В / ≤4 Вт, автономное питание до 5 лет

Цифровой интерфейс

RS 485 Modbus RTU

RS 485/232 HART/Modbus RTU

RS 485/232 HART/ Modbus RTU

RS 485/232 HART/Modbus RTU

RS 485/232 HART/Modbus RTU

RS 485/232 HART/Modbus RTU

RS 485 Modbus RTU

RS 485/232 HART/Modbus RTU

RS 485/232 HART/ Modbus RTU

RS 485/232 HART/Modbus RTU

RS 485/232 HART/Modbus RTU

RS 485/232 HART/Modbus RTU

Наличие частотного выхода

Да

Да

Да

нет

Нет

Нет

Да

Да

Да

нет

Нет

Нет

Внутренний архив данных

Минутный-7суток;

Часовой - 120 суток; суточный - 2 года; архив вмешательсв и тревог - по 3400 сообщений

Минутный-7суток;

Часовой - 120 суток; суточный - 2 года; архив вмешательсв и тревог - по 3400 сообщений

Минутный-7суток;

Часовой - 120 суток; суточный - 2 года; ар¬хив вмешательсв и тревог - по 3400 сообщений

Часовой – 104 суток; суточный – 600 суток; архив вмешательств – 2000 сообщений

Часовой - 104 суток; суточный - 600 суток; архив вмешательств - 2000 сообщений

Часовой - 104 суток; суточный - 600 суток; архив вмешательств - 2000 сообщений

Минутный-7суток;

Часовой - 120 суток; суточный - 2 года; архив вмешательсв и тревог - по 3400 сообщений

Минутный-7суток;

Часовой - 120 суток; суточный - 2 года; архив вмешательсв и тревог - по 3400 сообщений

Минутный-7суток;

Часовой - 120 суток; суточный - 2 года; ар¬хив вмешательсв и тревог - по 3400 сообщений

Часовой – 104 суток; суточный – 600 суток; архив вмешательств – 2000 сообщений

Часовой - 104 суток; суточный - 600 суток; архив вмешательств - 2000 сообщений

Часовой - 104 суток; суточный - 600 суток; архив вмешательств - 2000 сообщений

Степень защиты

IP65 (для составных частей располагаемых во взрывоопасной зоне);

IP54 (для составных частей располагаемых во взрывобезопасной зоне)

IP65 (для составных частей располагаемых во взрывоопасной зоне);

IP54 (для составных частей располагаемых во взрывобезопасной зоне)

IP65 (для составных частей располагаемых во взрывоопасной зоне);

IP54 (для составных частей располагаемых во взрывобезопасной зоне)

IP54

IP54

IP54

IP65 (для составных частей располагаемых во взрывоопасной зоне);

IP54 (для составных частей располагаемых во взрывобезопасной зоне)

IP65 (для составных частей располагаемых во взрывоопасной зоне);

IP54 (для составных частей располагаемых во взрывобезопасной зоне)

IP65 (для составных частей располагаемых во взрывоопасной зоне);

IP54 (для составных частей располагаемых во взрывобезопасной зоне)

IP54

IP54

IP54

Требования к прямым участкам (вход/выход)

10 D/3D

Либо 5D +формирователь потока/3D

Не требуются

10D/3D

Согласно ГОСТ 8.586.3

20D/5D

Согласно ГОСТ 8.586.1…5-2005

10 D/3D

Либо 5D +формирователь потока/3D

Не требуются

10D/3D

Согласно ГОСТ 8.586.3

20D/5D

Согласно ГОСТ 8.586.1…5-2005

Измерение в прямом и обратном направлении потока

Да

Нет

Да

нет

Да

Да

Да

Нет

Да

нет

Да

Да

Suitable for sizes DN50 - DN1400

Working medium

pressure up to 25 MPa

Confirmed high stability of flow measurement (0.1%)

and accuracy of flow measurement (0.3%)

Reliable operation when metering unprepared gaseous media and in ultra-low ambient temperatures – down to -61°С

More than 11,000 flowmeters operating successfully at power facilities

Ultra-low

power consumption, self-contained power supply and wireless data

transmission

Built-in flow

adjuster and data archive

A wide range of designs to meet the requirements of diverse applications in the gas industry

A wide range of designs to meet the requirements of diverse applications in the gas industry

Comparative

table

(pdf, 27 Mb )

(pdf, 27 Mb )

A convenient table comparing the features of Vympel flowmeters. Which flowmeter is the optimal instrument for your application?

Your cart