Telemechanics

Inhibitor feed system

Inhibitor feed system

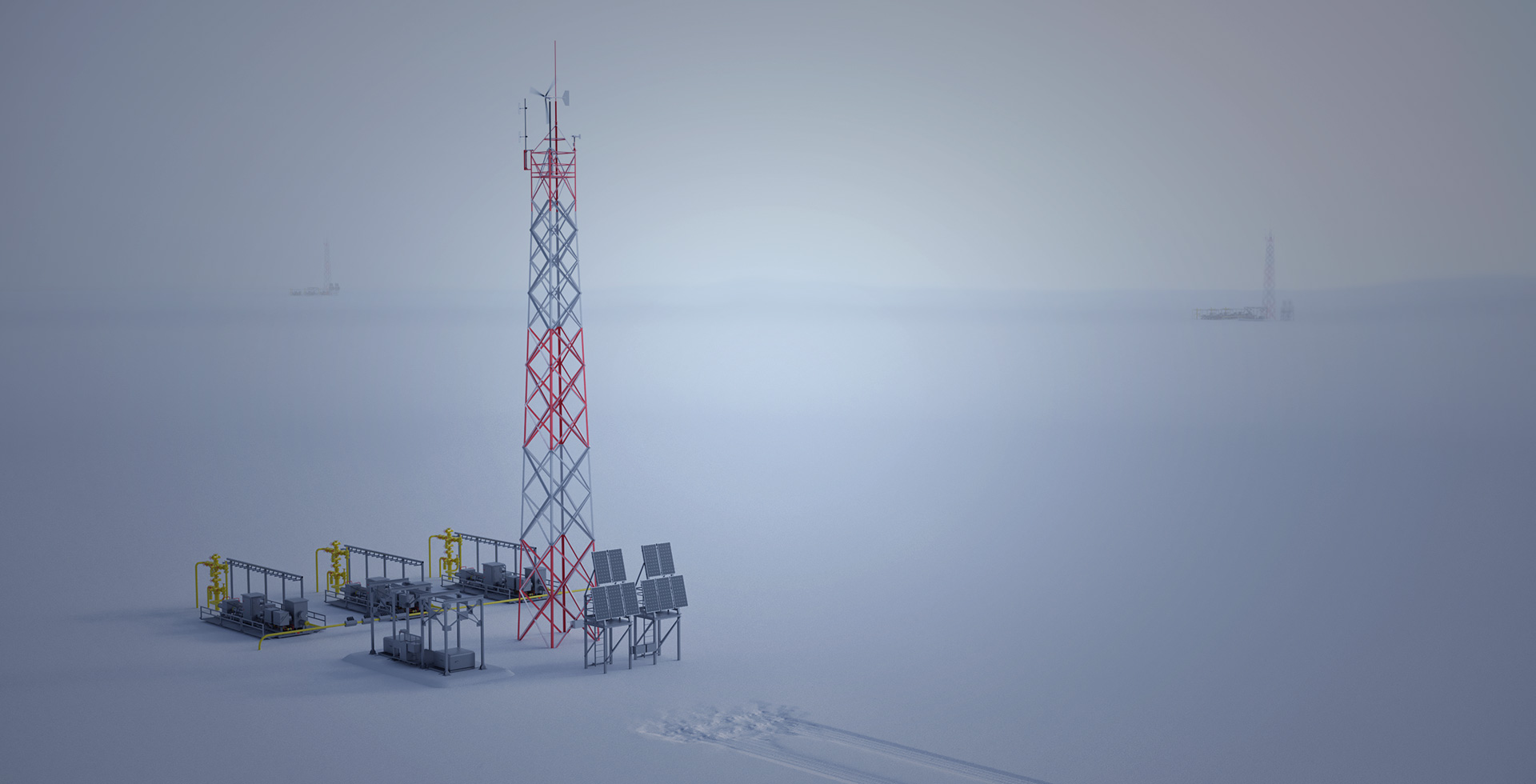

The inhibitor feed systems are designed for remote adjustment of inhibitor feed into the pipelines and process units of gas fields, gas well clusters, systems for low temperature separation (LTS) of gas in extreme climate oconditions.

The IFS have extra-low power consumption with possible autonomous operation.

The devices are designed for placement in explosion-hazardous zones of premises and exterior installations.

The IFS can operate in three main modes:

- continuous inhibitor feed at a set flow rate;

- continuous inhibitor feed at a set regulating stem position;

- periodic inhibitor feed at a set interval.

IFS models:

The IFS models vary by application facilities, number of channels and maximum carrying capacity of inhibitor feed channels, namely:

- SPI-02 – gas and gas concentrate production wells;

- SPI-03(-01, -02, -03) – pipelines and process units of gas fields, LTS systems; 1(3) inhibitor feed channels;

- SPI-04 – ipelines and process units of gas fields, LTS systems; 4, 8, 12 or 16 inhibitor feed channels.

In the SPI-02 and SPI-04 systems, the modes are set with a built-in control module on command initiated from the operator's workstation located in an explosion safe zone or from the local automation controller.

In the SPI-03 system, the modes are set with a regulator unit on command initiated from the operator's workstation located in an explosion safe zone or from the local automation controller.

The inhibitor flow rate is changed by a valve with electric drive.

Continuous measurement of the set flow rate in the SPI-02 and SPI-03 systems is provided with HyperFlow-3Pm instrument on a special restrictive orifice. In the SPI-04 system, the flow calculation based on the measured values of pressure, pressure difference and temperature, as well as electric drive control at a set algorithm, are done by the control unit.

Application fields

Gas production, storage and preparation facilities in gas well clusters, main gas and oil pipelines.

Signature features:

Possible remote regulation;

Extra-low power consumption;

Possible operation in extreme climate conditions;

Integration in any telemetry systems

Integration in any telemetry systems via RS-485 interface;

Finished control loop;

Possible continuous control of inhibitor flow rate

Possible continuous control of inhibitor flow rate even with 24V power supply disabled (autonomous operation mode)

Characteristics

SPI-02

Number of inhibitor feed channels

1

Measured medium

Inhibitor (Liquid)

Measured parameters

Temperature, pressure, pressure difference, liquid flow rate, valve stem position Operating pressure limit

Предельное рабочее давление

25; 32 MPa

Dynamic flow adjustment range

0 to 100%

Pressure differenced at "input-output" points, max

5 MPa

Maximum carrying capacity of each channel

115 kg/h

Dynamic flow measurement range

1:25

Flow measurement error

±3% from measured value plus "zero" stability

"Zero" stability

±0.3% from maximum flow rate

Power supply voltage

20 to 30 V

Maximum current consumed by the device, max

3 A (in adjustment mode);

0.1 A (in idle mode)

0.1 A (in idle mode)

Set flow rate maintenance mode

Manual and automatic

Interface type for communication with a telemetry system

RS-485

Environment temperature

-60°C to +60°C

Weight

120 kg

HIDE ALL CHARACTERISTICS

SPI-03 abd SPI-03-01

Number of inhibitor feed channels

1

Measured medium

Inhibitor (Liquid)

Measured parameters

Temperature, pressure, pressure difference, inhibitor flow rate and regulator unit position

Operating pressure limit

16; 25 MPa

Dynamic flow adjustment range

0 to 100%

Pressure differenced at "input-output" points, max

0.4 to 5 MPa

Maximum carrying capacity of each channel

100, 300, 600, 900 kg/h

Dynamic flow measurement range

1:25

Flow measurement error

± 3% from measured value plus "zero" stability

"Zero" stability

± 0.3% from maximum flow rate

Power supply voltage

20 to 30 V

Maximum current consumed by the device, max

4.7 A (in adjustment mode);

0.1 A (in idle mode)

0.1 A (in idle mode)

Set flow rate maintenance mode

Manual and automatic

Interface type for communication with a telemetry system

RS-485

Environment temperature

-60°C to +60°C

Weight

300 kg – SPI-03; 120 kg – SPI-03-01

HIDE ALL CHARACTERISTICS

SPI-03-02

Number of inhibitor feed channels

1

Measured medium

Inhibitor (Liquid)

Measured parameters

Temperature, pressure, pressure difference, inhibitor flow rate and regulator unit position

Operating pressure limit

16; 25 MPa

Dynamic flow adjustment range

0 to 100%

Pressure differenced at "input-output" points, max

0.4–1.5 MPa or 1.5–5.0 MPa

Maximum carrying capacity of each channel

100, 300, 600, 900 kg/h

Dynamic flow measurement range

1:25

Flow measurement error

± 3% from measured value plus "zero" stability

"Zero" stability

± 0.3% from maximum flow rate

Power supply voltage

20 to 30 V

Maximum current consumed by the device, max

4.7 A (in adjustment mode);

0.1 A (in idle mode)

0.1 A (in idle mode)

Set flow rate maintenance mode

Manual and automatic

Interface type for communication with a telemetry system

RS-485

Environment temperature

-60°C to +60°C

Weight

65 kg (on a frame); 110 kg (in a cabinet)

HIDE ALL CHARACTERISTICS

SPI-03-03

Number of inhibitor feed channels

3

Measured medium

Inhibitor (Liquid)

Measured parameters

Temperature, pressure, pressure difference, inhibitor flow rate and regulator unit position

Operating pressure limit

16; 25 MPa

Dynamic flow adjustment range

0 to 100%

Pressure differenced at "input-output" points, max

0.4–1.5 MPa or 1.5–5.0 MPa

Maximum carrying capacity of each channel

100, 300, 600, 900 kg/h

Dynamic flow measurement range

1:25

Flow measurement error

± 3% from measured value plus "zero" stability

"Zero" stability

± 0.3% from maximum flow rate

Power supply voltage

20 to 30 V

Maximum current consumed by the device, max

4.7 A (in adjustment mode);

0.1 A (in idle mode)

0.1 A (in idle mode)

Set flow rate maintenance mode

Manual and automatic

Interface type for communication with a telemetry system

RS-485

Environment temperature

-60°C to +60°C

Weight

195 kg (on a frame); 300 kg (in a cabinet)

HIDE ALL CHARACTERISTICS

SPI-04

Number of inhibitor feed channels

4, 8, 12, 16

Measured medium

Inhibitor (Liquid)

Measured parameters

Temperature, input and output pressure, pressure difference, flow rate and control valve open percentage

Operating pressure limit

16; 25 MPa

Dynamic flow adjustment range

0 to 100%

Pressure differenced at "input-output" points, max

0.3 to 5 MPa

Maximum carrying capacity of each channel

100 kg/h

Dynamic flow measurement range

1:25

Flow measurement error

± 3% from measured value plus "zero" stability

"Zero" stability

± 0.3% from maximum flow rate

Power supply voltage

20 to 30 V

Maximum current consumed by the device, max

3.5 A (in adjustment mode);

0.35 A (in control mode with line supply;

0.035 A in control mode with autonomous power supply from an accumulator source

0.35 A (in control mode with line supply;

0.035 A in control mode with autonomous power supply from an accumulator source

Set flow rate maintenance mode

Manual and automatic

Interface type for communication with a telemetry system

RS-485

Environment temperature

-60°C to +60°C

Weight

300 kg

HIDE ALL CHARACTERISTICS

Operating manuals

Certificates

Product order

Telemechanics complex for gas well clusters

Modular solutions for the automation of difficult to access gas condensate fields

Your cart