Telemechanics

Linear telemechanics system

Linear

telemechanics system

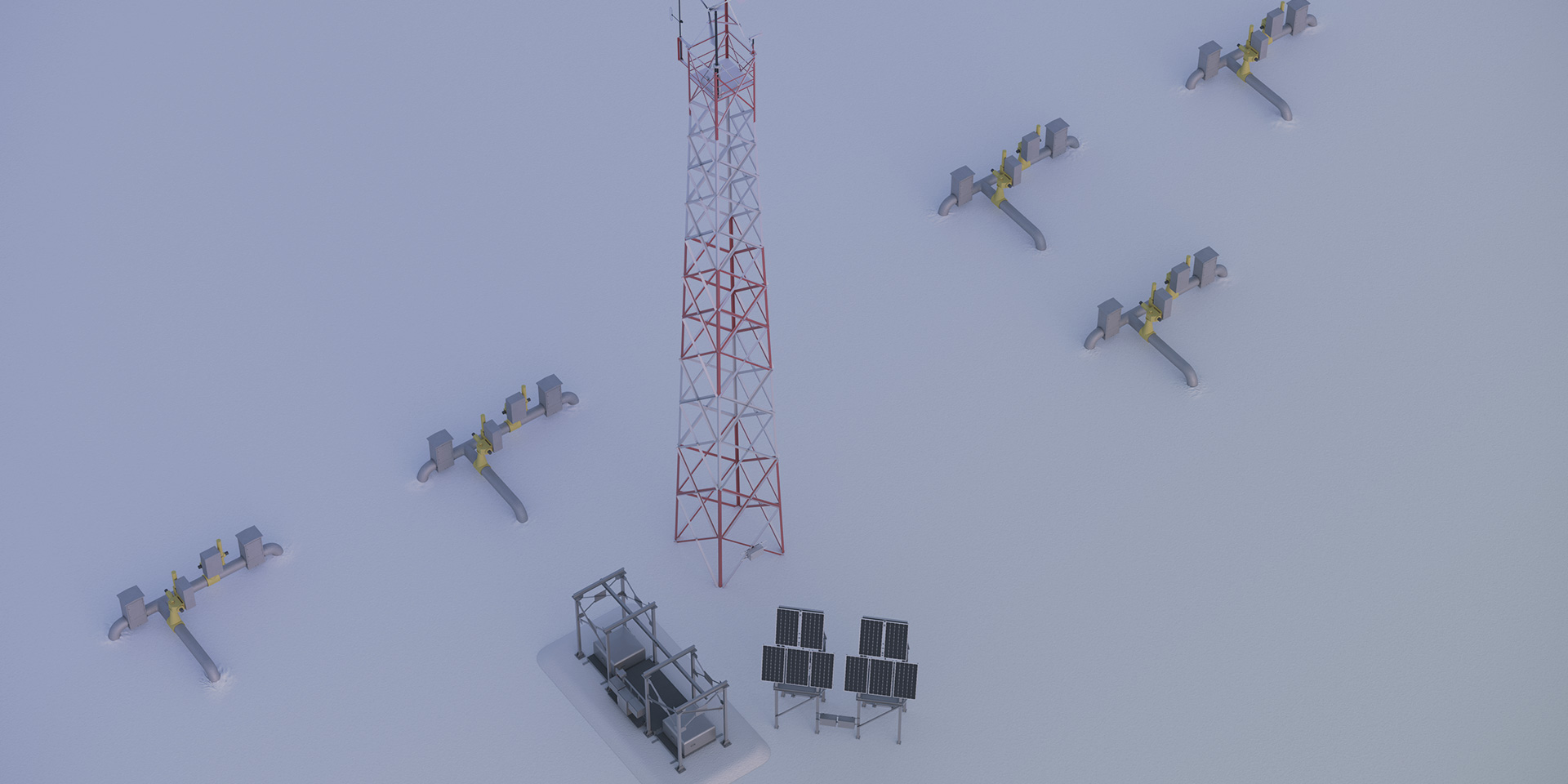

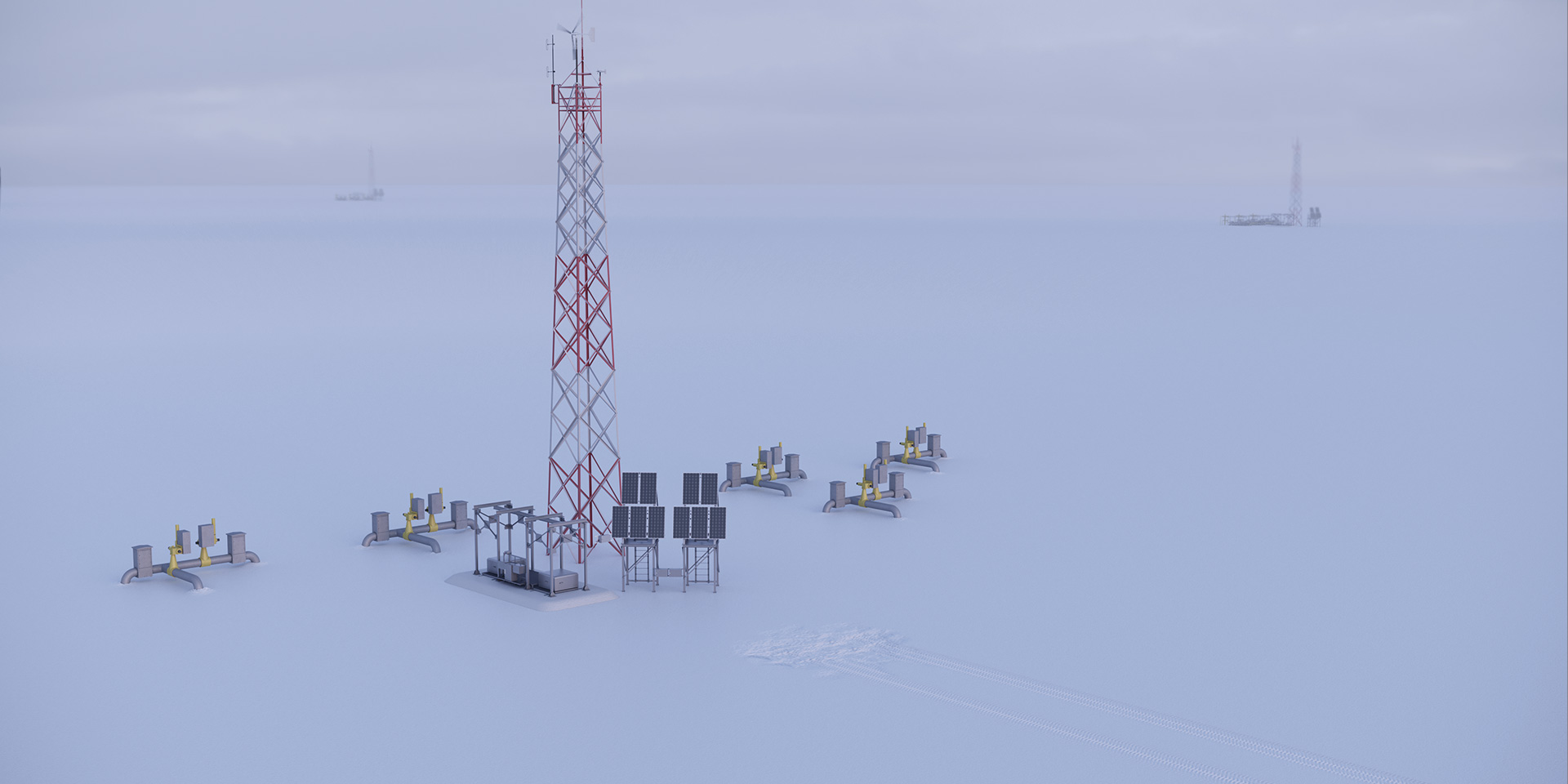

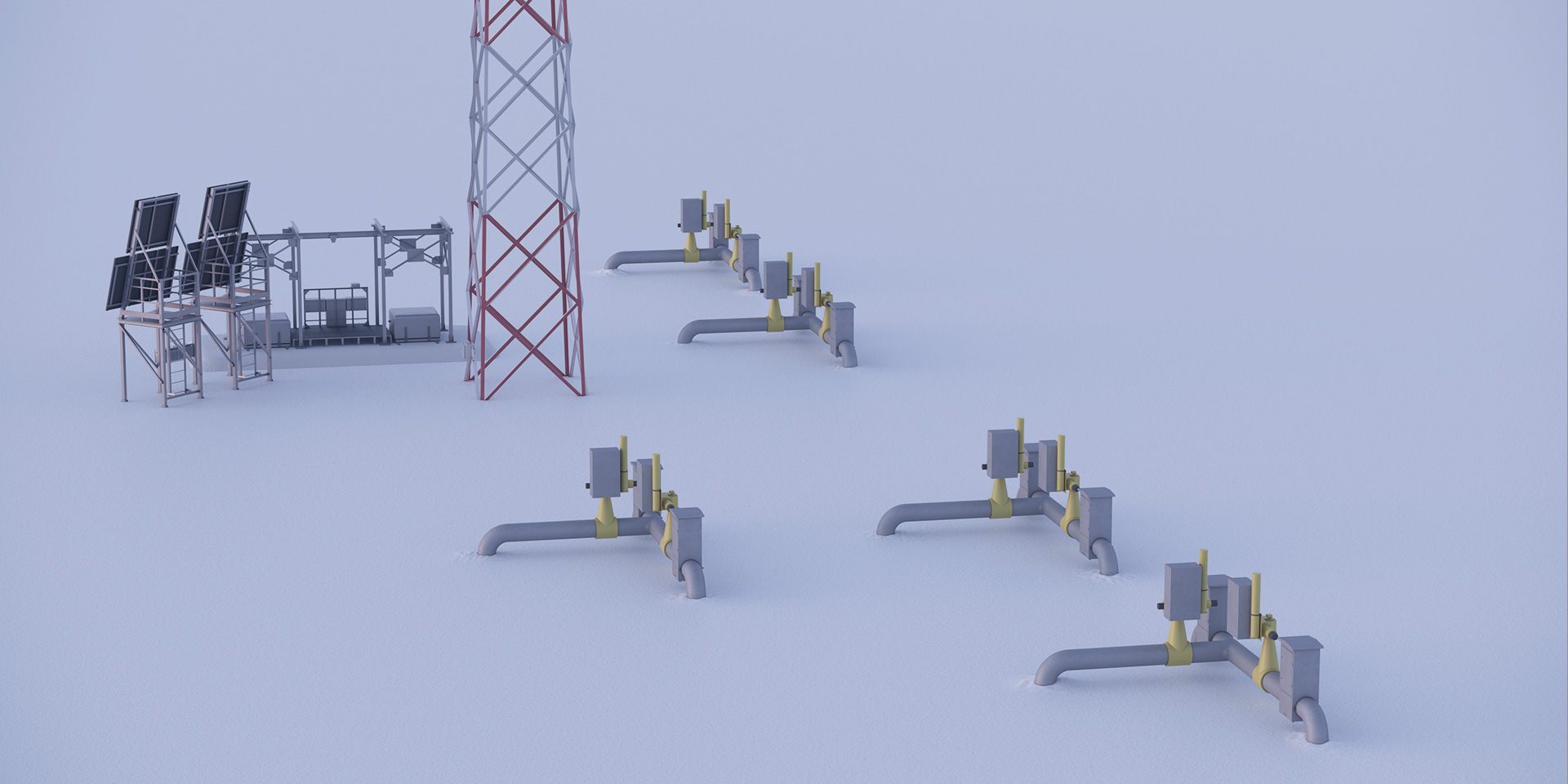

The pipeline linear telemechanics system (PLTM) is designed to ensure the safe transportation of liquid hydrocarbons by means of continuous monitoring of the piping system parameters and control of the pipeline actuators, detection of possible leaks for quick cut-off of emergency areas, control over routine operations for pipeline cleaning and diagnostics, control of the cathode protection system, power supply to the telemechanics units and connected equipment controlled by the system.

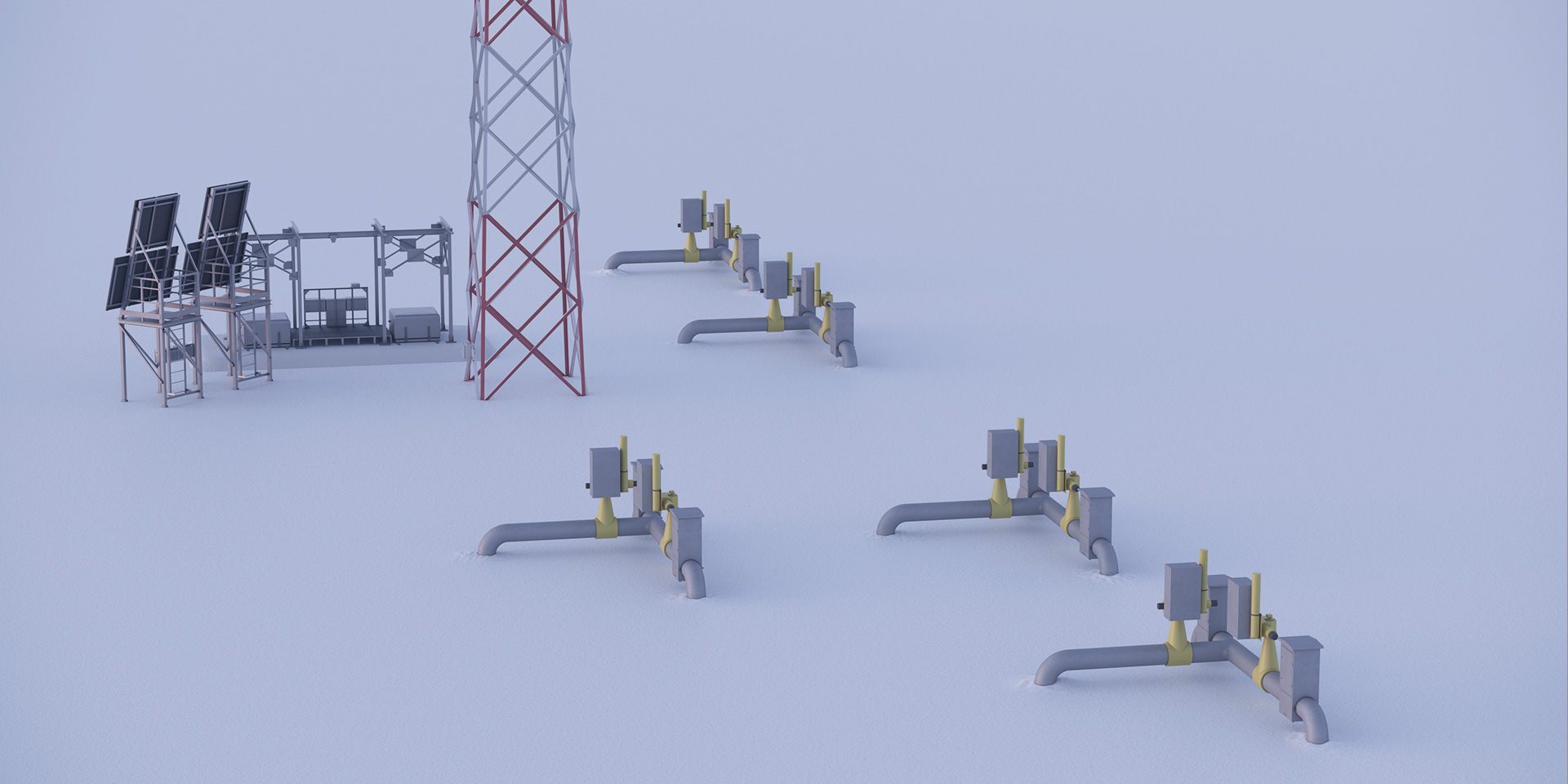

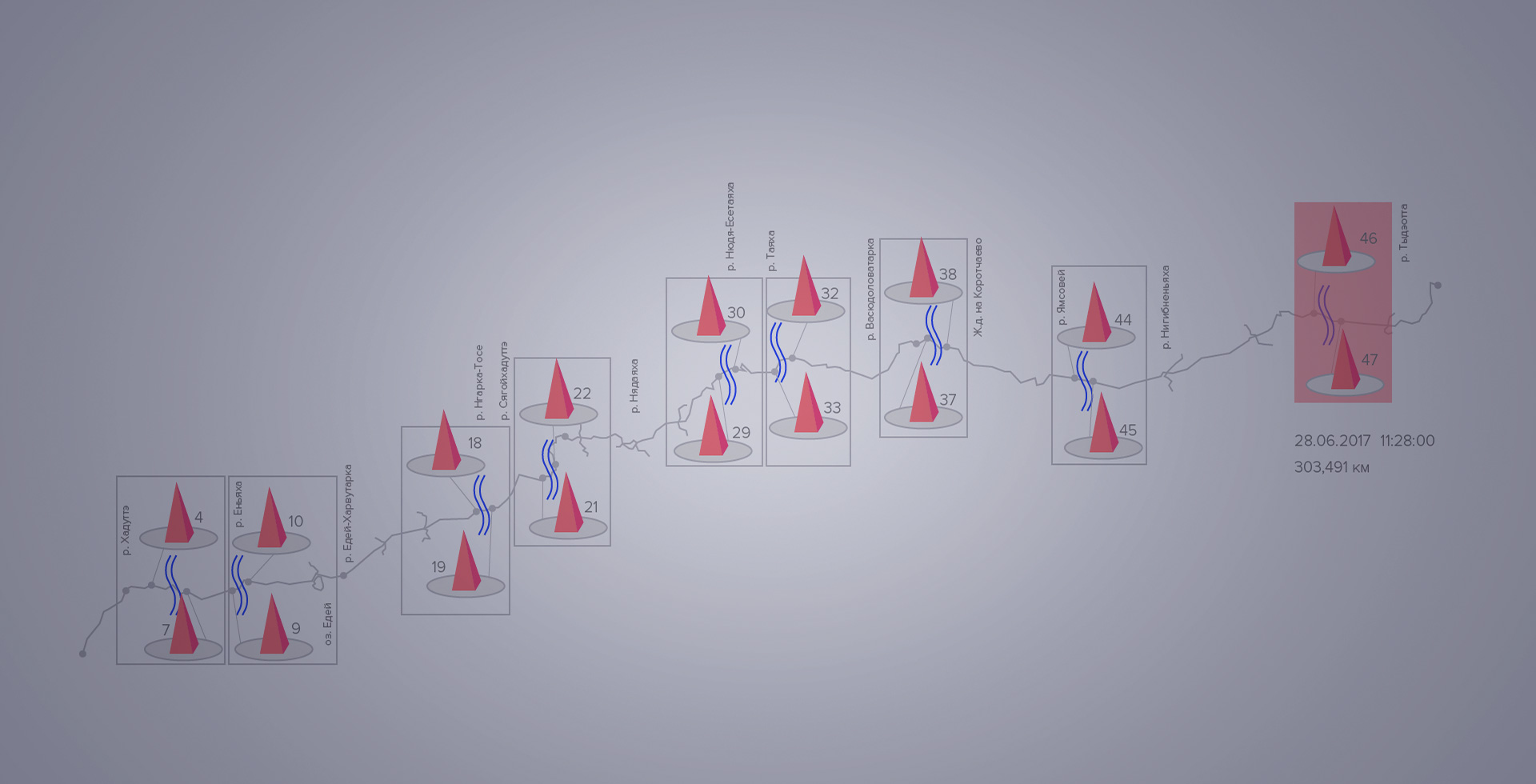

SLTM has two levels: upper level – control point (PU); lower level – controlled points (CPs) distributed along the length of the pipeline and the base controlled points (BCPs).

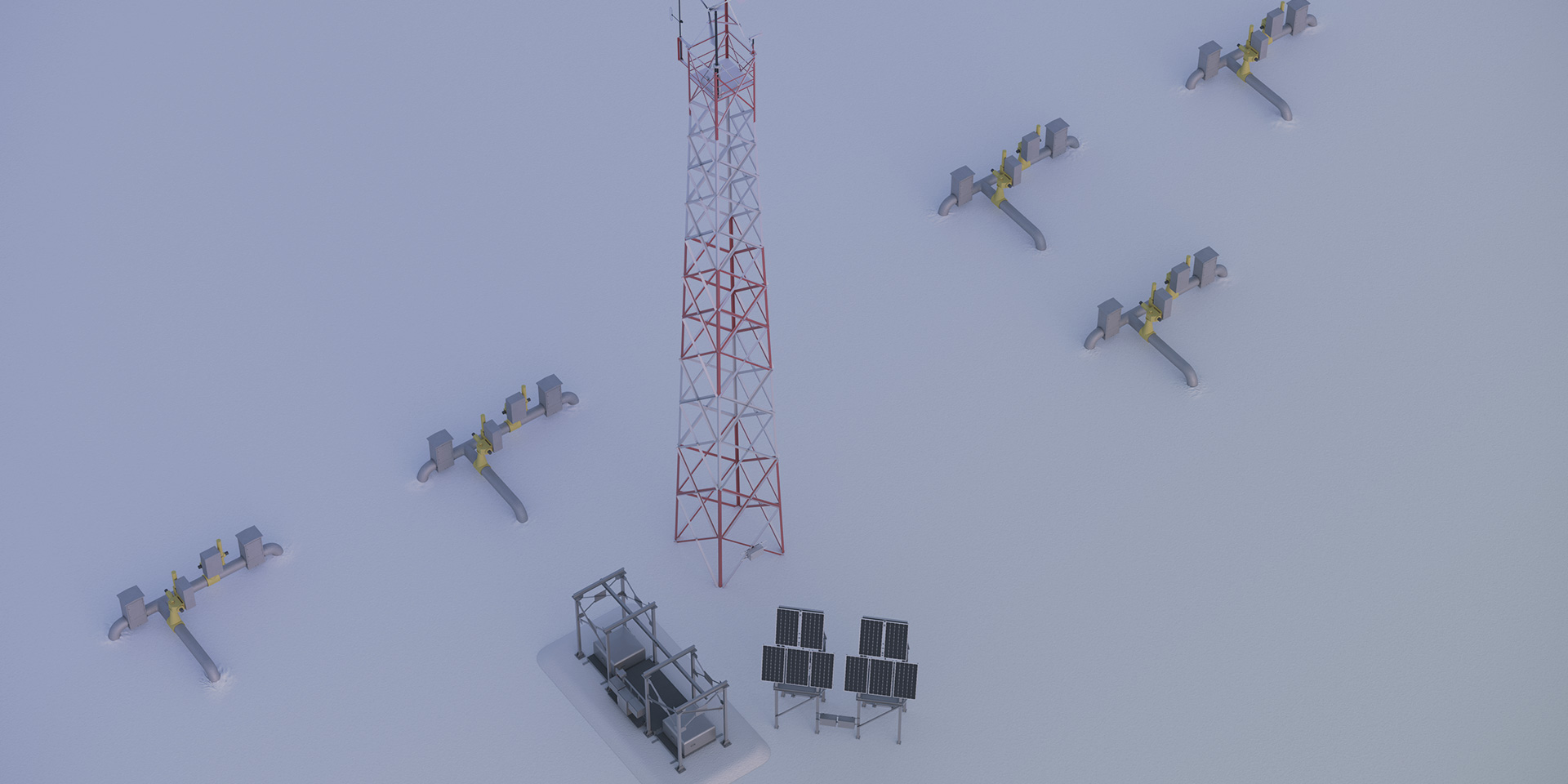

Wireless communication between the components of the SLTM is via VHF-band radio signal between the CP and the BCP and radio relay communications between the BCP and the PU. CPs and the BCPs are equipped with individual radio transceivers.

Power for control points can be supplied by an external power supply and/or Vympel’s proprietary autonomous power complex (APC), which uses renewable energy sources and is a part of the CP.

Use of the PLTM at production sites not connected to power grid is possible due to the ultra-low power consumption of all system components that have been developed by SPA Vympel.

Wireless communication between the components of the SLTM is via VHF-band radio signal between the CP and the BCP and radio relay communications between the BCP and the PU. CPs and the BCPs are equipped with individual radio transceivers.

Power for control points can be supplied by an external power supply and/or Vympel’s proprietary autonomous power complex (APC), which uses renewable energy sources and is a part of the CP.

Use of the PLTM at production sites not connected to power grid is possible due to the ultra-low power consumption of all system components that have been developed by SPA Vympel.

Main functions:

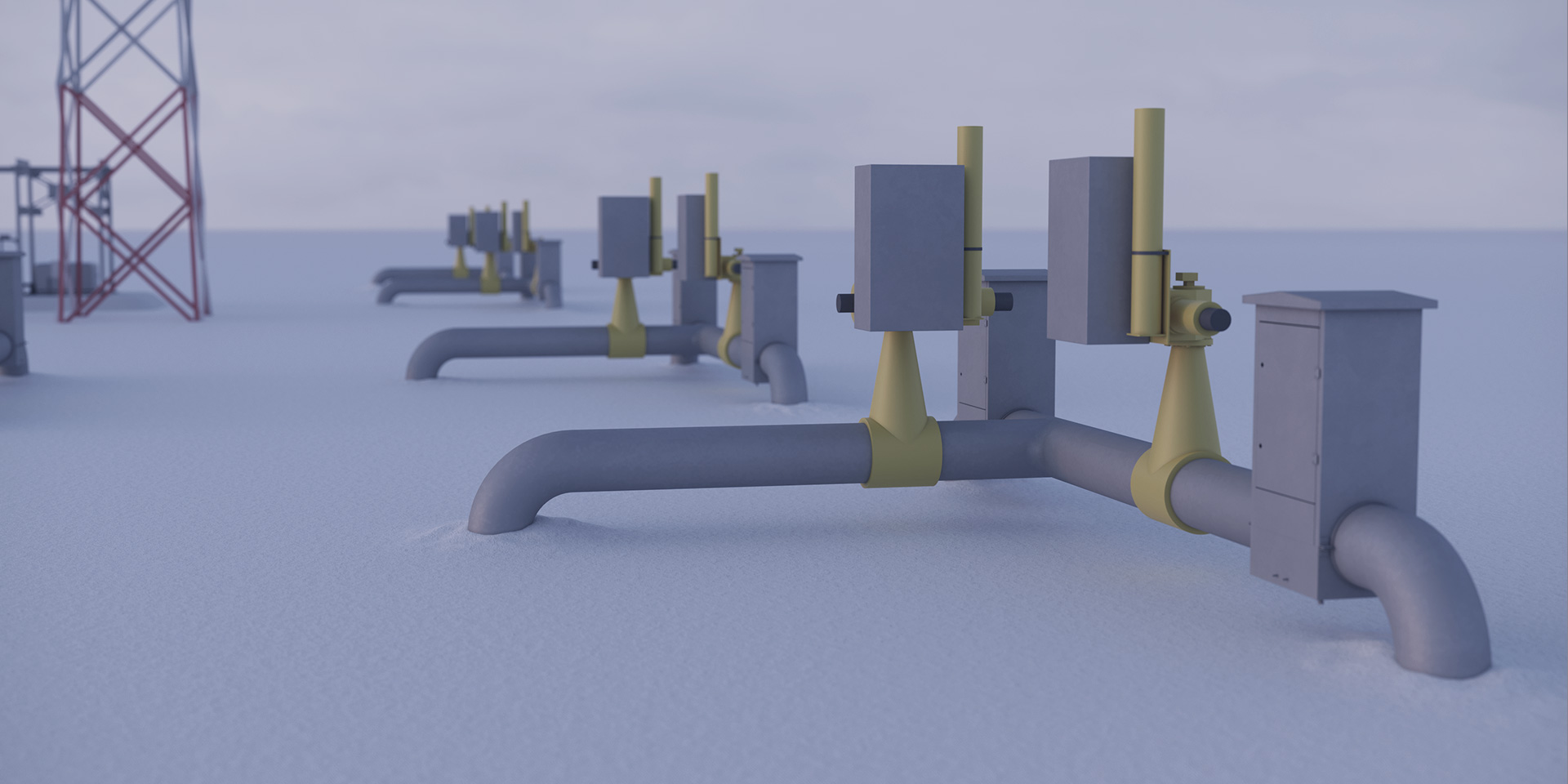

- automatic collection, archiving, and transmission of data regarding the parameters of the medium transported in the underground product pipeline;

- electrochemical protection of the pipeline (ECP);

- leak detection of transported medium(LDS);

- control of the profression of the diagnostic and cleaning equipment (DAC);

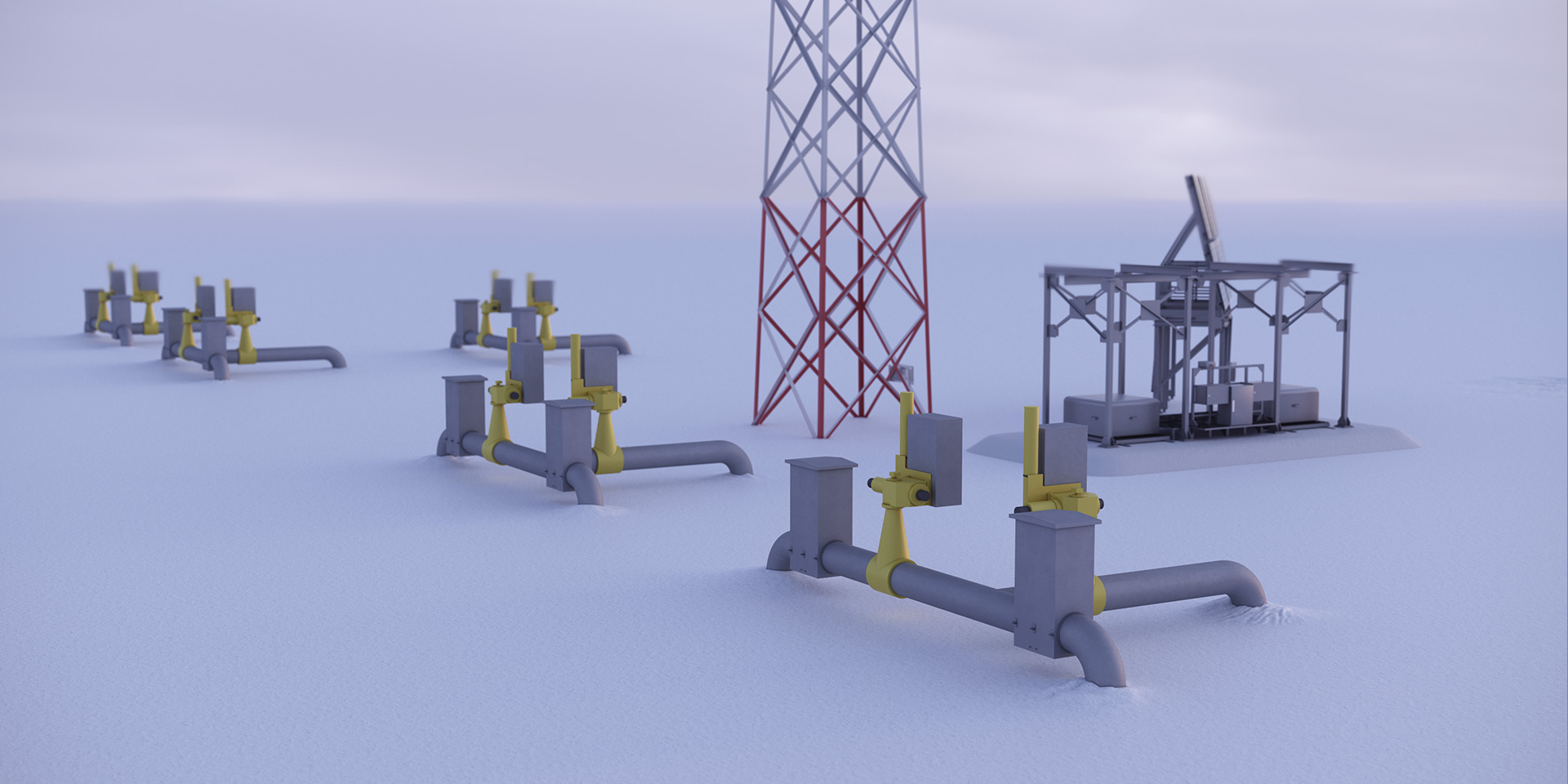

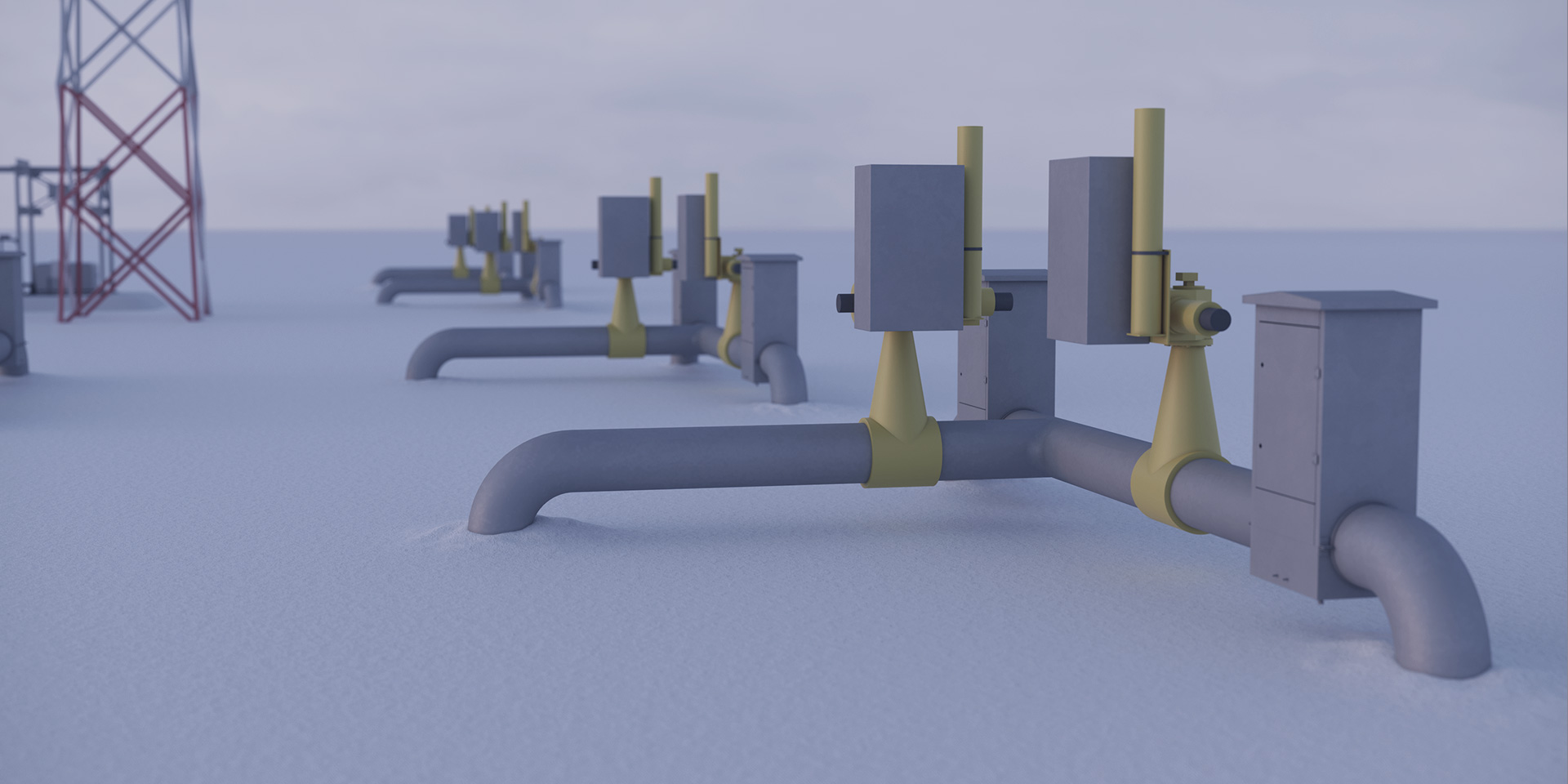

- control of actuators (ball valves);

- gas contamination control (GCC)

- security alarm;

- supply power for the pipeline’s technological equipment with or without access to an external power supply.

Fields of application

- Condensate pipelines

- Gas pipelines

- Oil pipelines

Signature

features

Reducing capital construction costs

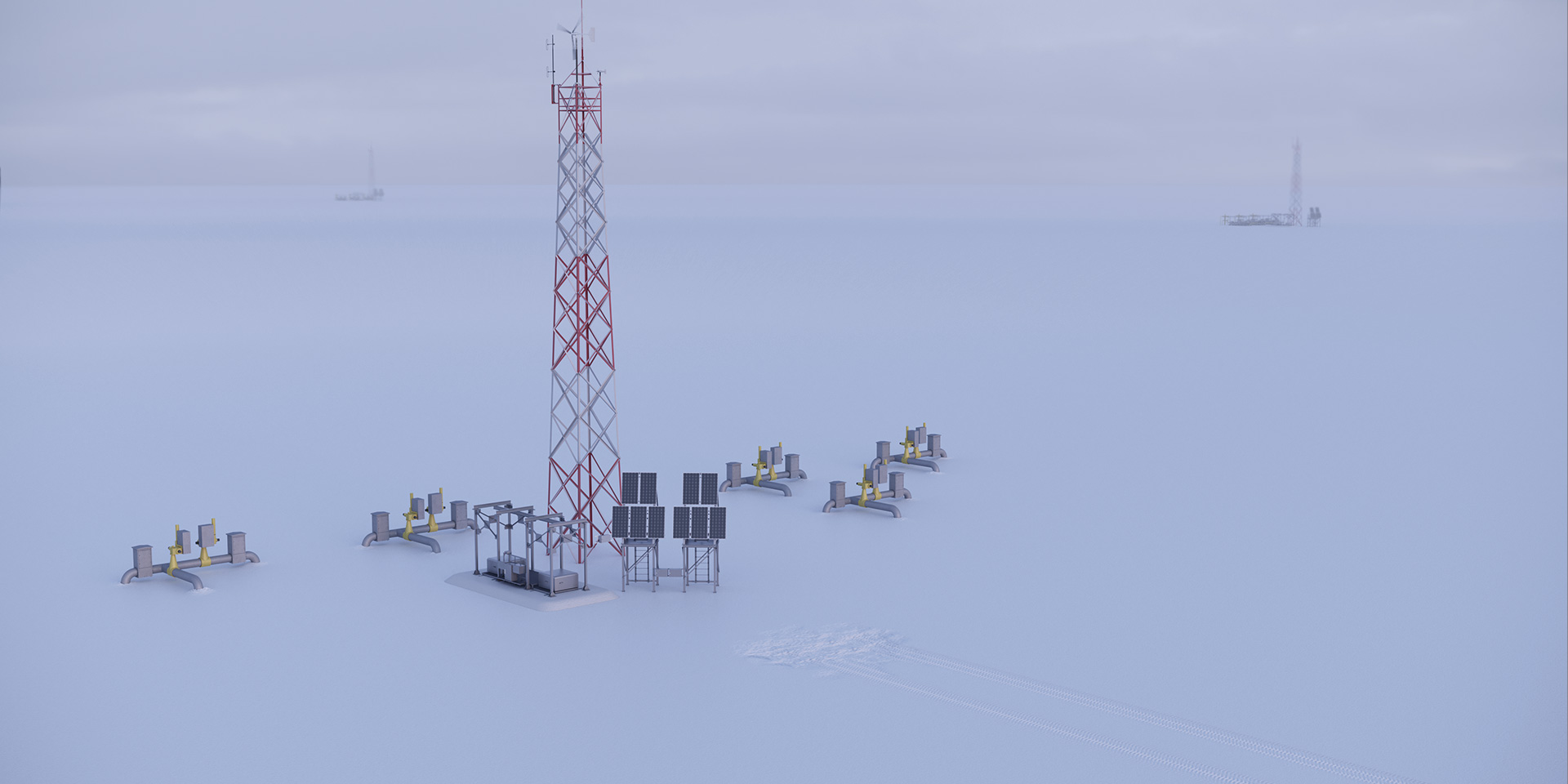

Power supply for operation of controlled points using renewable energy sources (wind and solar energy), resulting in a significant reduction in the facility’s capital construction costs (no power lines).

No electricity costs

Operation at extremely low ambient air temperatures (from -60 °C) in the Far North powered by onsite renewable sources thanks to the ultra-low power consumption of all SLTM components. As a result, energy costs, including heating, are greatly reduced.

Operation at high ambient air temperatures

Operation at high ambient temperature (up to +50 °C) in tropical conditions without air conditioning systems thanks to the ultra low heat emission of system components.

Unmanned maintenance technologies

Due to high system reliability and an advanced diagnostic system for monitoring the condition of the equipment, the SLTM is practically maintenance free.

Communication via wireless radio link

Automated digital communication between the upper and lower levels is carried out via wireless radio communication.

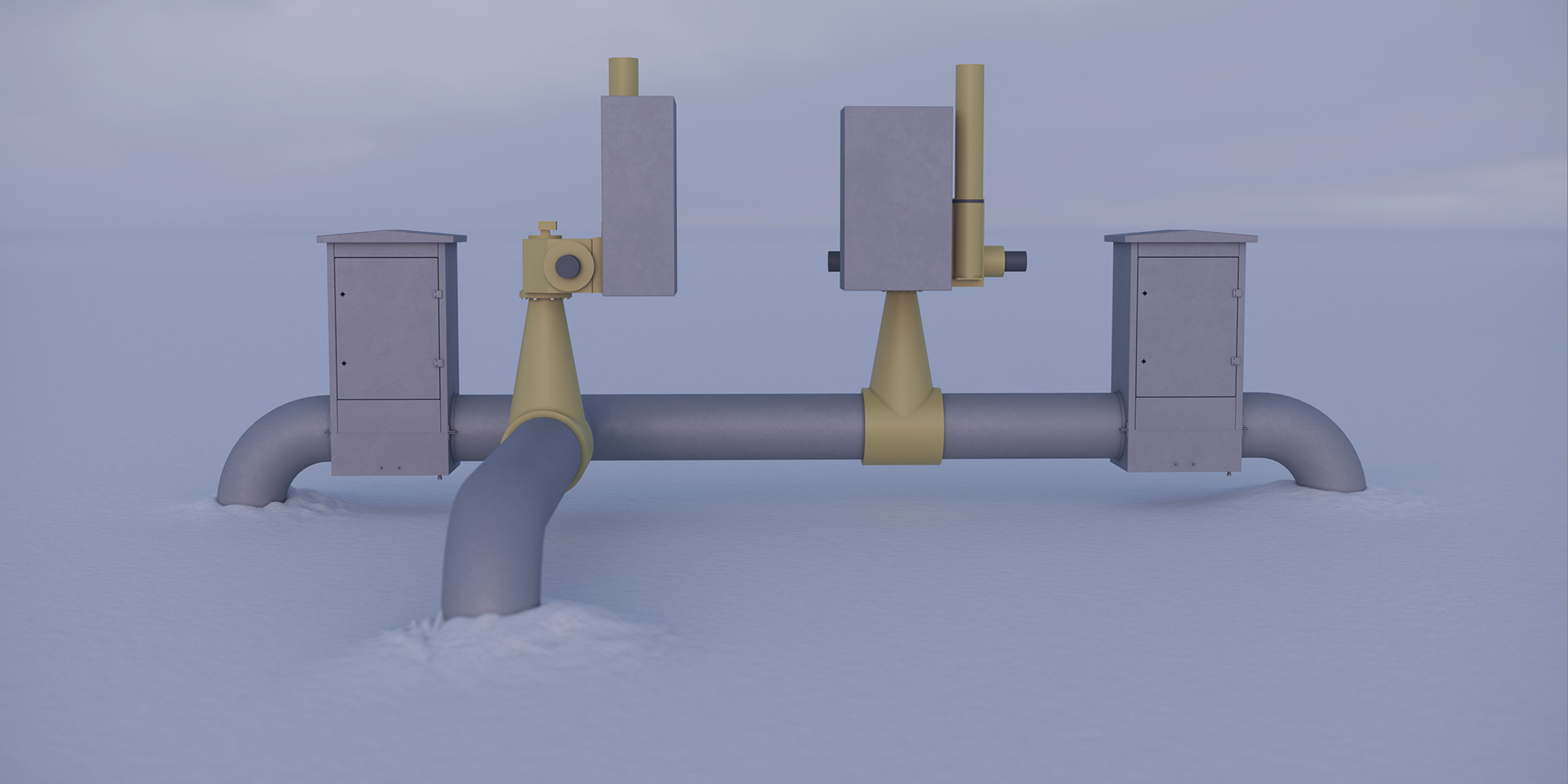

Remote control of the line valve

Remote control of the line valve by means of an electro-pneumatic control unit powered by the solar module; diagnostics analysis of the valve unit’s technological parameters; and continuous 24-hour operation.

Characteristics

The LV ICS components (except for the control room equipment, base controlled points, and equipment located in the underground modules) can function in an environment with the following parameters:

ambient temperatures from -60 °C to +50 °C; relative humidity up to 95% at 35 °C as long as there is no moisture condensation

The LV ICS provides data transfer from each controlled point to the control panel

The LV ICS base controlled point gathers data from the nearest controlled points via VHF radio.

The connection between the base controlled point and the subordinated controlled points is provided by

VHF radio modems

Monitoring analysis of the status of the LV ICS controlled point is provided by internal diagnostics

Diagnostics include: checking the status of the instrumentation, actuators, built-in storage batteries, and controllers, including equipment and communication channels fault monitoring. When a fault is detected, an alarm message is generated.

show all Characteristics

Principle of operation:

The LV ICS is a system for gathering processing, presenting and storing technological information about the parameters of the transported medium environment and the condition of pipelines.

The LV ICS has two levels

- upper level: control point (PU)

- lower level: controlled points (CP), distributed along the length of the pipeline and the base controlled points (BCP).

The connection between the components of LV ICS is established:

- via VHF radio channel between the CP and the BCP

- via radio-relay communication between the BCP and the PU

Radio transceivers are used as transmitting and receiving devices in the CP and the BCP.

The LV ICS includes 5 types of controlled points:

- electrified, combined with the diagnostic and cleaning equipment (DAC) launching unit

- electrified

- electrified DAC receiving units

- non-electrified

- non-electrified DAC launching and receiving units

The LV ICS includes a leak detection system (LDS): a software and hardware package that processes information from sensors located on the pipeline in real time to detect and locate leakage and establish when leakage occurs. The system uses several leak detection methods: pressure wave analysis, volumetric balance analysis, and pressure profile analysis.

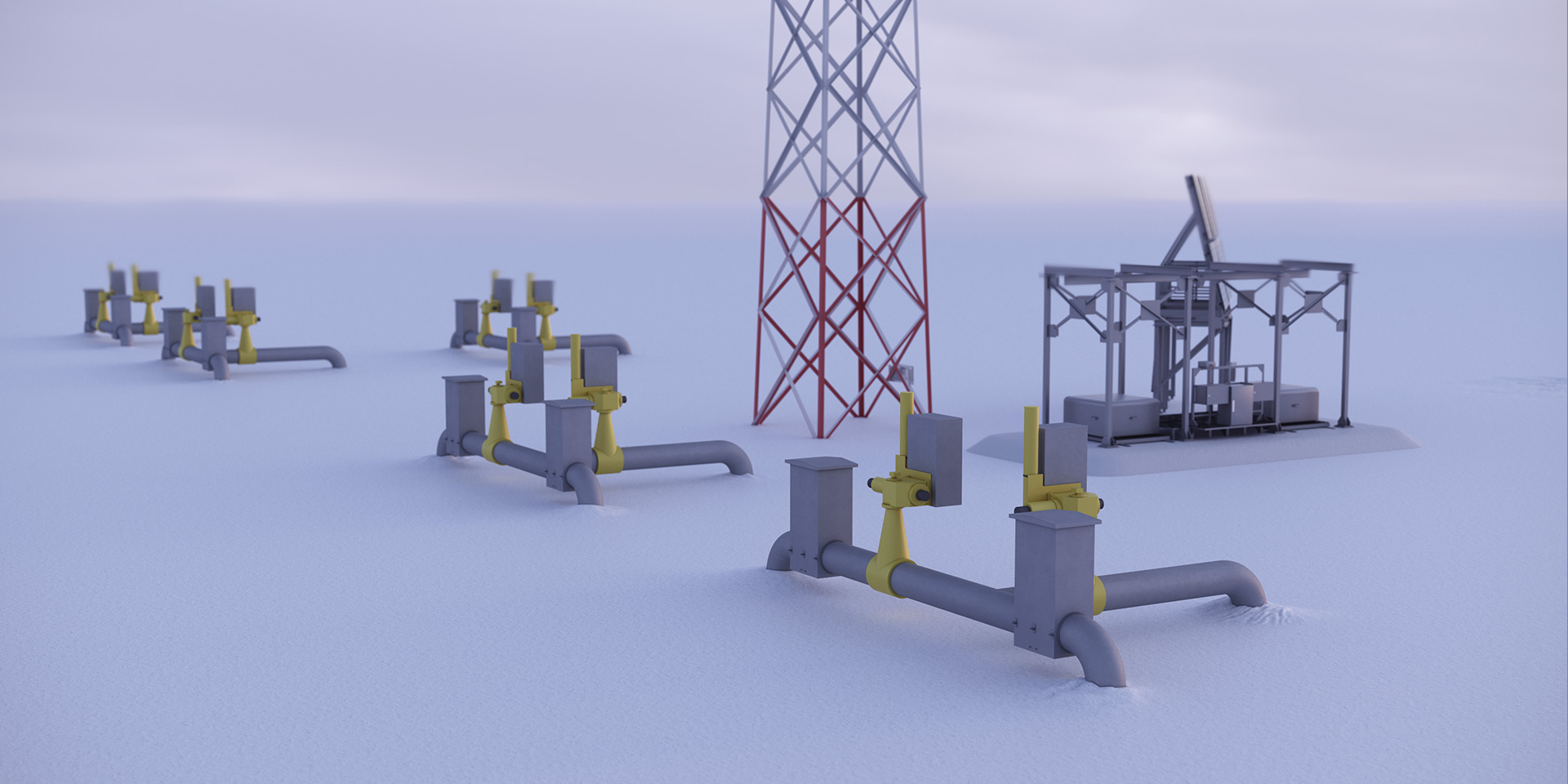

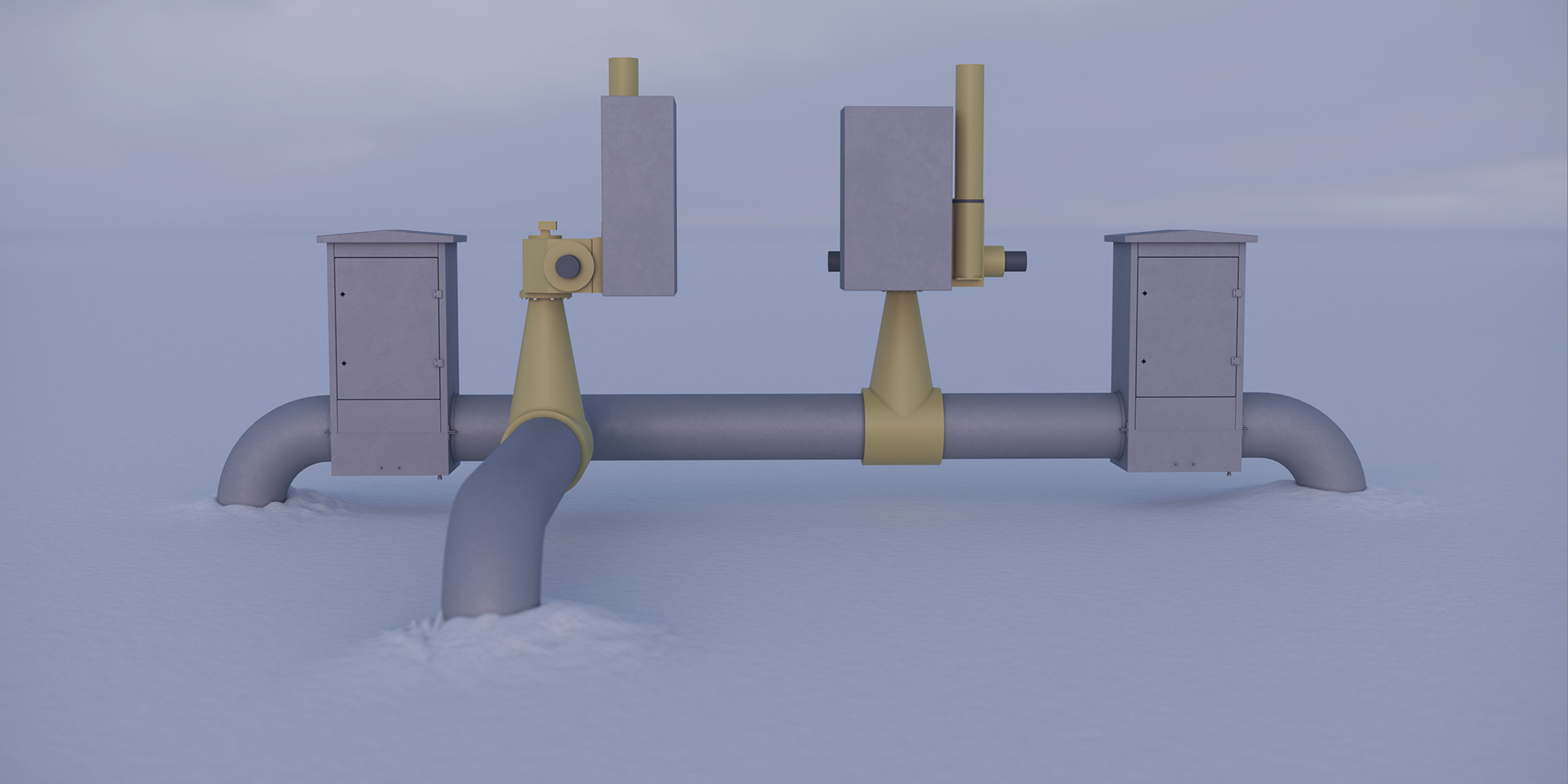

The following equipment is included in non-electrified CPs:

- complex sensors - nodes (P and T) HyperFlow-3Pm

- electrohydraulic ball valve actuators

- solar modules

- wind generators

- CP and valve station perimeter fencing security sensors

- cathodic protection station

The following equipment is included in electrified CPs:

- complex sensors - nodes (P and T) HyperFlow-3Pm

- electric ball valve actuators

- backup power supply

- CP and valve station perimeter fencing security sensor

- cathodic protection station

During operation, the LV ICS runs diagnostics of the hardware and software in the CP, BCP and PU units. Diagnostics include checking the status of: the pressure and temperature control units, the built-in storage batteries, and the controllers, as well as monitoring equipment, actuator, and communication failures. The hardware is diagnosed automatically. Information on hardware faults is displayed on the AWS screens, indicating the specific faulty component or unit and the occurrence is recorded in the event log. Self-diagnosis of controllers is incorporated into the built-in hardware and software.

Configuration*

show package contents

Main set

Dispatching kit electronics module

Operator workstation

Printer

Power source

AWS application software

The system and special software for the Complex, configuration and programming tools

AWS application software

A set of antenna-feeder devices

Operating documents

Instruction manuals

Layout

Calibration procedures

* may be altered. Clarified at the time of order

show package contents

Product order

Contact us

Leak detection system

Reducing capital construction costs

Power supply for operation of controlled points using renewable energy sources (wind and solar energy). As a result - a significant reduction in the cost of capital construction of the facility (no power lines).

No electricity costs

Operation at extremely low temperatures of ambient air (from -60°С) in the Far North in conditions of absence of external power supply due to ultra-low power consumption of all components of the SLTM. The result is a lack of energy costs, including heating.

Функционирование при высоких температурах окружающего воздуха

Функционирование при высоких температурах окружающего воздуха (до +50 °С)

в условиях тропических климатических поясов без систем кондиционирования оборудования благодаря сверхнизкому тепловыделению компонент системы.

Unmanned maintenance technologies

Due to the high reliability of the systems and the developed system for diagnosing the condition of the equipment, SLTM practically does not need any maintenance.

Communication over a wireless radio link

Automatic communication between the lower and upper levels is carried out digitally via the wireless radio communication channel.

Remote control of the line valve

Remote control of a line valve with an electro-pneumatic control unit with power supplied from a solar module, diagnostics of valve site technological parameters, and continuous 24-hour operation.

Your cart