Flowmeters

HyperFlow-3Pm

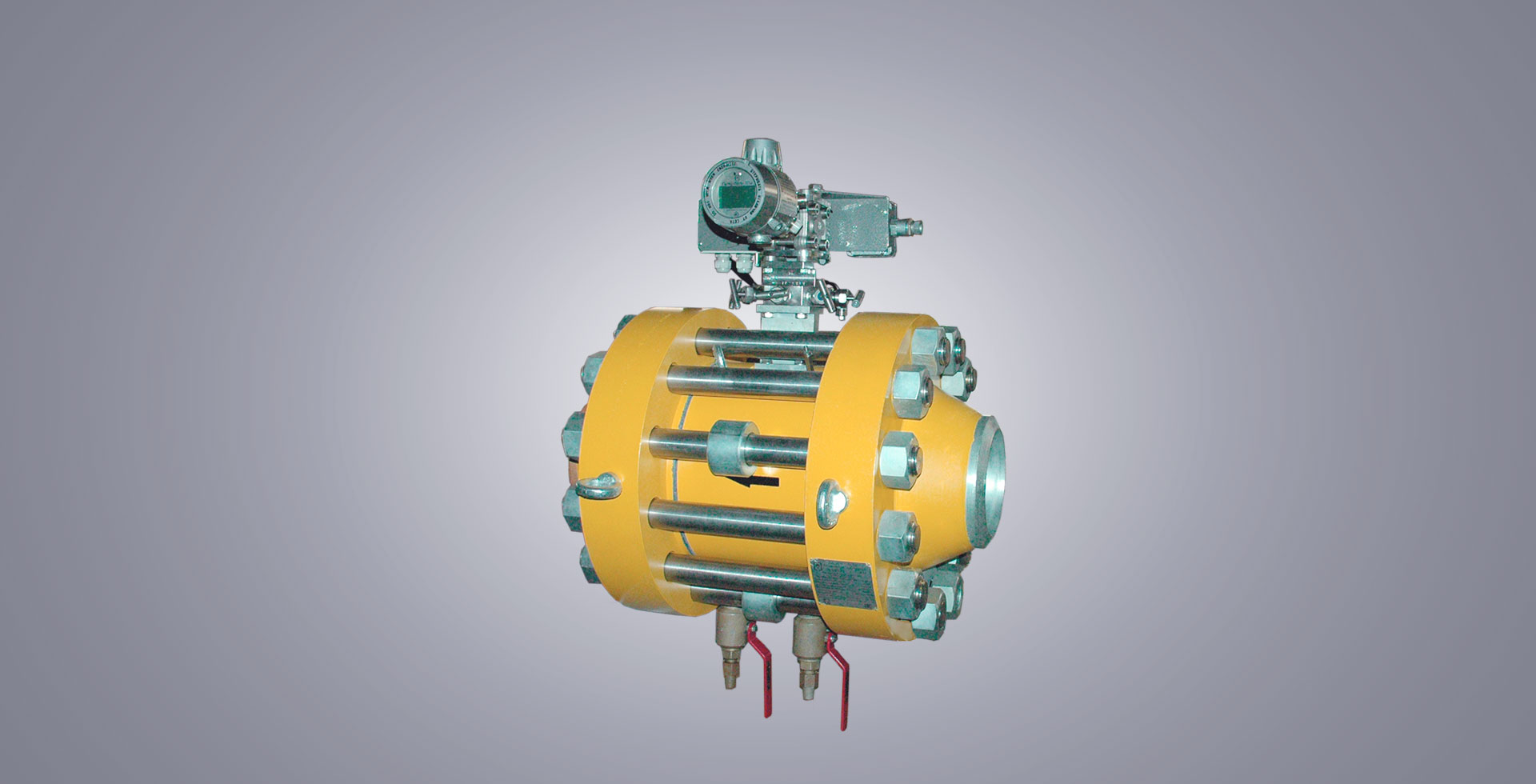

HyperFlow-3Pm

HyperFlow-3Pm complex sensor with a flow calculation unit is designed for measuring the flow and quantity of liquid and gaseous media. It can be used as a

multi-parameter sensor using six channels for measuring pressure/pressure difference (differential pressure) and one channel for temperature.

The basis of operation of the HyperFlow-3Pm is to measure the flow rate:

- using the variable pressure difference method;

- using gas volume flowmeters (operation in the correcting mode).

When used with orifice plates for high flows or with the NSU, the HyperFlow-3Pm can be used to measure flow rate and quantity in either direction of flow.

The use of an additional differential pressure sensor extends the flow measurement range.

The HyperFlow-3Pm is a fully autonomous instrument that is powered by the built-in battery and operates for up to five years.

The HyperFlow-3Pm is designed to measure flow using various primary transducers in accordance with the relevant regulatory documents:

- standard constriction devices in accordance with GOST 8.586.1 - GOST 8.586.5-2005;

- special constriction devices in accordance with RD 50-411-83;

- flow transducers with conical orifice of a relative diameter of 0.4–0.64 in accordance with MI 3572-2016;

- primary flow transducers with hydraulic resistance in accordance with MI 3580-2017;

- non-standard constriction device (NSU) in accordance with KRAU2.833.006 TU;

- volume flow sensors and meters with pulse output in accordance with GOST R 8.740-2011.

The physical properties of natural gas are calculated in accordance with the requirements of GOST 30319.1-2015 - GOST 30319.3-2015, GOST R 8.662-2009, GOST R 8.770-2011.

Application fields

- commercial metering units for measuring the flow of natural gas, water, steam, other liquid and gaseous media

- gas production and storage wells

- gas condensate production wells as a part of the DFR-01 two-phase flow meter

- HyperFlow-TM telemechanics systems as the pressure and temperature measurement units

- gas odorization systems for measuring odorant flow

- LNG flow measurement systems

Intended use

The HyperFlow-3Pm is designed for use in industrial and municipal facilities as an independent measuring tool, as well as in automated metering and control systems or for information transfer to other systems. The HyperFlow-3Pm is designed for operation in explosion hazardous areas and is labeled with the explosion protection marking: 1ExibllВT5XSignature features:

High measurement accuracy

High measurement precision in the dynamic flow measurement range and in the operating temperature range of −60°C

to +60°C. High measurement precision across the pressure difference and temperature measurement

channels is achieved by means of the use of primary transducers with special circuit solutions and sensor calibration technology.

Possibility for the elimination of output signal dependency on the set reference values

The calculation unit, along with the primary difference and pressure transducer, is put in a thermal chamber,

where the output signal dependency on specified reference values is removed for the entire pressure and temperature range.

Guarantee of accuracy in the range of measurement by means of the differential pressure channel

The calibration results, which are individual for each sensor, are stored in the memory of the calculation unit and are then used in the

measurement process. In this way, accuracy is ensured over the range of the differential

pressure channel from 1 to 100% and thus extend the flow measurement range up to 1:10 over the entire operating temperature range.

Characteristics

Type of primary element (internal diameter of the measuring pipeline, mm)

orifice with angle tapping (50–3000 mm),

orifice with flange or three-radius tapping (50–1000 mm);

nozzle ISA 1932 (50–1000 mm);

Venturi nozzle (65–500 mm);

Venturi pipe (50–1200 mm);

non-standard constriction devices (92; 144 mm);

special constriction device: orifice with conical inlet (12.5–100 mm)

- flow transducer with a conical orifice, relative diameter 0.1–0.64 (MI 3572-2016) (8–12.5 mm)

- primary flow transducer with hydraulic resistance (MI 3580-2017) (0.15–4.2 mm)

nozzle ISA 1932 (50–1000 mm);

Venturi nozzle (65–500 mm);

Venturi pipe (50–1200 mm);

non-standard constriction devices (92; 144 mm);

special constriction device: orifice with conical inlet (12.5–100 mm)

- flow transducer with a conical orifice, relative diameter 0.1–0.64 (MI 3572-2016) (8–12.5 mm)

- primary flow transducer with hydraulic resistance (MI 3580-2017) (0.15–4.2 mm)

Flow measurement range using a standard constriction device

from 10 to 5,500,000 Sm3/h (gas including natural gas);

from 0,01 to 4,000 t/h (water vapor);

from 0,8 to 20,000 t/h (liquid including water)

from 0,01 to 4,000 t/h (water vapor);

from 0,8 to 20,000 t/h (liquid including water)

The range of flow measurement using a special constriction device (orifice with a conical inlet)

liquid 1 to 5,000 kg/h

gas 1 to 200 Sm3/h

gas 1 to 200 Sm3/h

Flow measurement range when using a flow converter with a conical orifice with a relative diameter of 0.1-0.64 (MI 3572-2016):

liquids from 1 to 1000 kg/h

gas (including natural gas) from 0.1 to 500 Sm3/h

gas (including natural gas) from 0.1 to 500 Sm3/h

Flow measurement range when using a volume flow meter (sensor) in the corrector mode

from 40 to 40,000 Sm3/h (gas, including natural gas)

Liquid flow measurement range when using a primary flow transducer with hydraulic resistance (MI 3580-2017)

from 0.001 to 120 kg/h

Thermal power measurement range

from 0.05 to 5,000 Gcal/h

Calorific value measurement range

from 0.4 to 200,000 GJ/h

Relative error limits, %:

flow calculation

±0,01; ±0,05

thermal energy calculation

±0,05; ±0,3

Excess pressure measurement upper limits, MPa

0.25; 0.6; 2.5; 6; 16; 25; 32; 60;

fraction error δ = ± (0.01+0.1(Р/Рmах))

fraction error δ = ± (0.01+0.1(Р/Рmах))

Absolute pressure measurement upper limits, MPa

0.25; 1; 3; 6;

fraction error δ = ± (0.01+0.1(Р/Pmах))

fraction error δ = ± (0.01+0.1(Р/Pmах))

Pressure difference measurement upper limits, kPa

6; 10; 25; 40; 100; 250;

fraction error δ = ± (0,01+0,1(dР/dРмах))

fraction error δ = ± (0,01+0,1(dР/dРмах))

Pressure difference and pressure channel measurement range

1 : 100

Flow measurement range

1 : 10; up to 1 : 40 using an additional differential pressure sensor

Temperature measurement limits, °C

copper RTTs with α=0.00428 °C-1: -180...+200; platinum RTTs with α=0.00385 or 0.00391 °C-1: -200 to +400

Temperature measurement error

± 0,25°С

Time measurement error

± 0,01%

Hourly data recording trace archive size

104 days by pressure, pressure difference, medium temperature, accumulated flow and heat output channels

Daily data recording trace archive size

600 days by pressure, pressure difference, medium temperature, accumulated flow and heat output channels

Interventions trace archive size

2000 messages

Power supply

Network: from the intrinsically safe barrier BIZ-002; Autonomous: from the built-in power supply 45 000 hours

Average lifetime

25 years

Verification interval

From 1 to 3 years (depending on the S, A, B, V or G accuracy design)

Dimensions, mm

160х103х260 (electronic unit)

Weight, kg

no more than 10 (electronic unit)

Operating conditions

Ambient temperature from -60 to + 60 °С

Ingress protection design

At least IP 54 according to GOST 14254-96

Designation of the document used as the basis for manufacturing the instrument

KRAU1.456.001-01 TU

show all Characteristics

Questionnaire

Configuration*

show package contents

Main set

HyperFlow-ZPm compound sensor with a flow calculation unit

Excess (absolute) pressure sensor

Pressure difference sensor;

Resistive temperature transducer;

Power supply unit;

Portable terminal;

Sensor adjustment kit (connection cable, CD with software);

Magnetic key;

Operation manual.

Optional equipment (on special order):

Junction box;

Spark protection barrier;

Verification kit;

A set of accessories and assembly parts.

* may be altered. Clarified at the time of order

show package contents

Operating manuals

Certificates

- Certificate of approval of HyperFlow-ZPm measuring device type

- Certificate of conformance with TR TS 012:2011 "On safety of equipment designed for work in explosion hazardous area"

- Ex-application

- Ex-application (addendum)

- MI type specification

- Certificate of conformance with TR TS 020:2011 "Electromagnetic compatibility of technical means"

Product order

HyperFlow-ISA gas flow meter

The flowmeter based on the standard constriction device: ISA 1932 nozzle

Your cart