The Next Generation in Moisture Analysis.

Oil and Gas Innovation speaks with SPA Vympel, who is a leading developer and manufacturer of automation equipment used in gas production, transportation and distribution. Vympel helps our readers understand more about the field of gas analysis, particularly the measuring of the dew point, hydrocarbon condensation, and hydrocarbon concentration level using laser technology. We also learn more about their FAS-W analyser, which is their next generation moisture analyser technology.

OGI: Could you start by explaining Vympel’s credentials and experience in terms of your products and services for the Oil and Gas sector? Could you tell our readers the breadth of your experience, how long the company has been active, and its reach?

Vympel: Vympel was founded over 30 years ago. At that time, technological solutions from western-based companies were not very accessible in the Russian market, so our founder Alexander Derevyagin, developed new technology to meet the need for a reliable water dew point solution. He founded Vympel to manufacture and sell it in the Russian market. Since then we have developed this technology further and expanded our expertise and product range to include several types of flowmeters, leak detection systems, autonomous off-the-grid gas production sites and all- terrain vehicles. For example, there are over 10,000 Vympel Hyperflow flowmeters in service. These developments have gone hand in hand with significant growth of the company. Vympel has evolved into the Vympel Group, which includes two manufacturing companies, an import/export company, and most recently for international sales and support, Vympel GmbH based in Germany. For about the past eight years, Vympel GmbH has been systematically developing new markets and new strategic partnerships, and now there are Vympel analysers in service all over the world.

OGI: What are Vympel’s main solutions of which it provides the industry?

Vympel: As I mentioned before, Vympel supplies chilled-mirror analysers for measuring the water dew point and hydrocarbon condensation temperature of natural gas. We supply state-of-the-art online and portable analysers, which have an unparalleled level of functionality. For example, the portable units offer microscopic resolution of the condensate as it develops on the mirror’s surface, and they require no refrigerant gas as they heat and cool the mirror electrically. Our dew point solutions are currently the main product line for international sales. However, we have been delivering cutting-edge flowmeters, both ultrasonic and differential pressure, to the Russian market for a number of years. Also, as I mentioned before, we have developed a number of different technologies for telemechanics and leak detection. All of these solutions have a history of years of service and it is planned to make these solutions available to the global market.

CONG Prima-2M automatic online water and hydrocarbon dew point transducer.

OGI: There are over 2000 SPA Vympel dew point analysers installed around the world, could you explain what these are and what they do?

Vympel: Our CONG Prima series of online dew point analysers are chilled-mirror devices that provide information about the quality of the gas. One of the most important factors in gas quality is its moisture content. For a variety of reasons, it is important that natural gas be essentially free of water vapour. For this reason, it is necessary to monitor how much water is present in the gas at any given point in the delivery chain. The best and most practical approach to determine this is to take a direct measurement of the water dew point using a chilled-mirror device, such as a Vympel CONG Prima series, FAS-W or Hygrovision portable series analyser. In a chilled-mirror analyser, the gas is passed over a “mirror” which is systematically cooled and heated. In our devices, when the mirror reaches the temperature where the water vapour begins to condense, the analyser recognizes the presence of this condensation and registers the temperature.

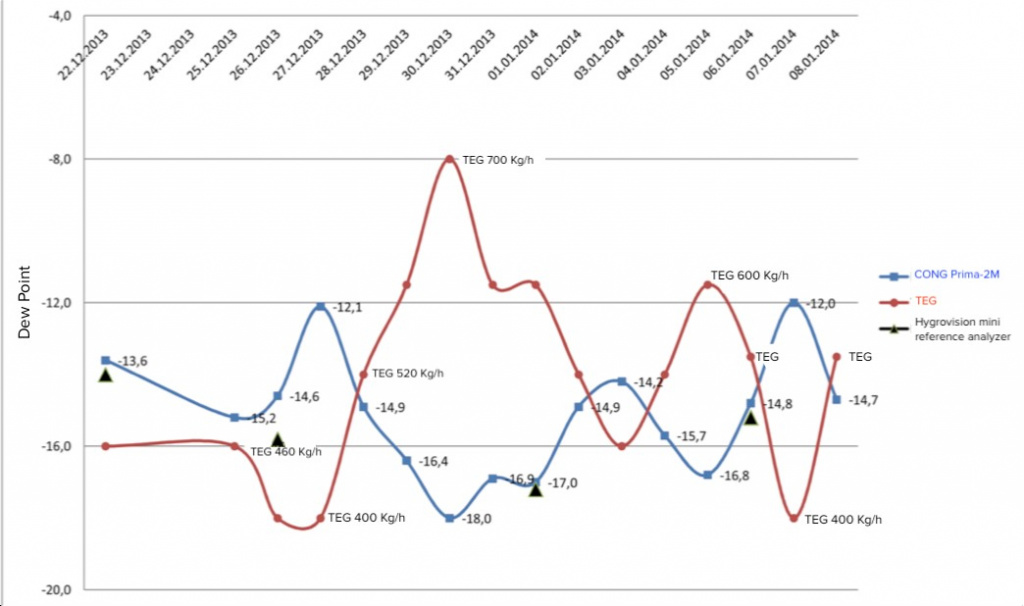

Installed to monitor moisture content in gas downstream of a glycol dryer, Vympel’s system also monitors the amount of glycol in the drying tower (graph of actual field measurements).

At this point it starts to heat the mirror slowly. When the water starts to evaporate again, the analyser registers this temperature as well. With these to data points it is easy to determine the equilibrium temperature, a.k.a. the dew point. The dew point is a physical property of the gas that is a result of the amount of water present, the temperature and the pressure. If we know the pressure and we measure the temperature, then we can easily derive the amount of water present. Chilled-mirror analysis is considered a first principles measurement. In addition to the water dew point, most of our analysers can also measure the hydrocarbon “dew point”, although dew point is actually a misnomer.

This value is actually the hydrocarbon condensation temperature. Again, this is a gas quality measurement, but despite the similarity in the name, it is actually providing somewhat different information. Without going into too much detail, it is important to measure the hydrocarbon dew point at what is known as the cricondentherm. This is the pressure that corresponds to the highest hydrocarbon condensation temperature. Hydrocarbons have a rather unexpected condensation behaviour which follows a retrograde curve... in other words the temperature goes up as the pressure goes up, but only to a point. After that the condensation temperature goes back down again.

OGI: Can you go into detail about your FAS-W moisture analyser?

Vympel: The FAS-W is a next generation moisture analyser. It uses technology based on the same foundations as the CONG Prima series – that is chilled-mirror analysis using a polarized laser and taking advantage of the phenomenon of total refraction – but it has a smaller mirror and a higher performance Peltier element so it can achieve lower temperatures. In addition, it has the ability to directly report the water content in terms of dew point, and with the input of pressure information, ppm, and mg/m3. What’s more, the FAS-W has both digital and analogue data ports and was designed to provide all this increased functionality at a significantly lower price compared to other chilled-mirror devices. To achieve this, the designers eliminated the user control panel from the FAS-W, which allowed for not only a decrease in cost and overall size, but also made it possible to increase the explosion protection rating to IIC.

OGI: Could you talk about your automation solutions in relation to helping customers with their hard to access fields and pipelines?

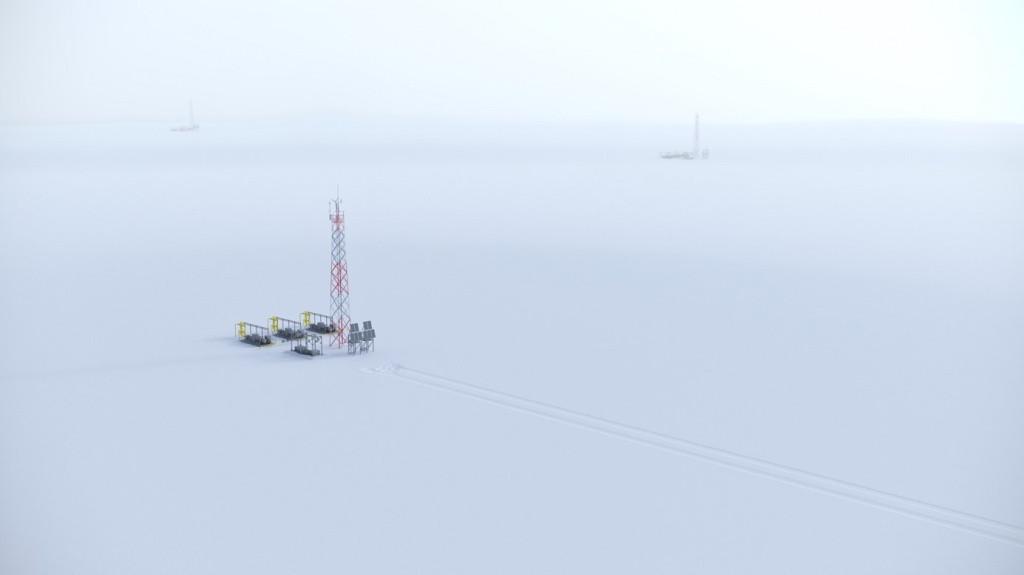

Vympel: There are vast natural gas resources in some of the most inaccessible areas of the Russian Federation. This is a pretty undeveloped region, largely because of the extreme climate. In order to develop these resources, it has traditionally been necessary to first build a road to the site and then to install electrical service. These are major up-front expenses before construction can even begin on the actual gas well. What we developed was an entire wellhead facility that operates on renewable energy using solar panels and wind turbines. This solution required us to develop all of the necessary technology and instrumentation based on the challenges of the climate as well as the limitations of the power supply. In addition, because of the remoteness of the installations, it was necessary that they function reliably without on-site staff. As a result, all of the technology can be operated remotely via wireless communication. On those rare occasions when it is necessary that someone visit the site, we have even developed a range of all-terrain vehicles, in sizes from a relatively small personnel carrier to large tandem vehicles with 8-wheel drive. Up to now, we have installed more than 1000 of these autonomous stations.

OGI: Could you talk a bit about your flowmeters and what they do?

Vympel: We currently offer two types of flow meter, ultrasonic and differential pressure. The units operating on the principle of differential pressure have been in service a number of years, and have proven to be extremely reliable and robust. These units are especially popular in the very challenging environments where the gas quality is compromised by contaminants, including dirt and sand. We also have one differential pressure flow meter that can measure a dual-phase medium, in other words, when there is both liquid and gas in the pipeline simultaneously. Our ultrasonic flow meters range in size from DN0.5 to DN1400. One of our units, the Vympel 100, has a unique geometry that allows us to do away with straight runs upstream and downstream from the flow meter. This unit is also capable of measurement over a very wide dynamic range. At the large end of our range of flowmeters are the DN1400 units.

One application for such a large flow meter is installation underground on the main pipeline as the main component of a single run commercial metering station. The first installation of such a station has been in operation for five years. A single-run metering station is another example of a solution that provides significant cost reductions to the operator. In addition, underground installation greatly reduces the above-ground footprint of the station and, when installed near a compressor station, can take advantage of existing infrastructure to provide for control measurements. The flow meter used for a single run station has a double set of 8 ultrasonic channels to ensure accuracy and stability of measurements.

OGI: Finally, could you enlighten our readers of a case study where you helped a client with your solutions?

Vympel: It is not uncommon to remove water vapour from gas by means of triethyleneglygol or TEG. This type of drying equipment is relatively common, and has been a standard solution for many years. Simply put, in this type of dryer, gas is injected at the base of a tower filled with TEG. As the gas percolates up through a tower the water molecules in the gas are captured by the hydrophilic TEG. As a result, the gas leaving the tower at the top is “dry”. Of course, the next link in the chain is to measure the humidity of the dry gas to confirm that the dryer is working properly. The main challenge to this measurement is TEG carry over, in other words, glycol that remains as an aerosol in the gas after it leaves the drying tower. Unfortunately, this glycol can quickly foul any analyser, so it is necessary to also filter the dry gas before any measurements are taken. Traditionally, this has meant placing a membrane filter between the gas sampling point and the analyser. The issue with a membrane filter is that it becomes saturated unpredictably, interfering with the quality of control measurements and requiring regular replacement of the filter element. In response to these drawbacks, we developed a patented inertia-gravity filter or IGF to achieve adequate filtration without a membrane filter. In our design, the gas flowing from the sampling point slowly fills a vertical tube before exiting to the analyser through a smaller, inner tube open at the top. While the gas is still in the larger tube aerosol contaminants, such as glycol, collect on the specially treated inner wall of this tube to form droplets. These droplets are heavy enough to run down to the bottom of the IGF where they are flushed out the bypass line. With this type of filter in place, our chilled- mirror hygrometer is protected from fouling.

Single-line gas metering station based on a Vympel-500 large diameter flow meter (DN1400).

Vympel ATV

We installed this system at a facility that was experiencing instability in the function of the drying equipment. In the lab we had determined that with our system in place that included the IGF and a CONG Prima- 2M analyser, with its high sensitivity and repeatability of measurement results, it should be possible to monitor not only the quality of the gas but also the function of the dryer. This is precisely what took place. We were able to demonstrate that the dew point of the gas was inversely proportional to the amount of glycol effectively adsorbing water from the gas in the tower. If there was not enough glycol or it had become saturated the dew point rose, whereas if the dew point dropped it was a sign that the dryer was over full with TEG and likely leaking TEG in the form of carry over. Our system provided a monitoring solution for both the gas quality and the dryer function, informing the operator when it was necessary to recharge the drying unit or reduce the amount of TEG in the tower to maintain optimal conditions.

Unmanned autonomous gas well powered by renewable energy source.