Telemechanics

Leak detection system

Leak detection system

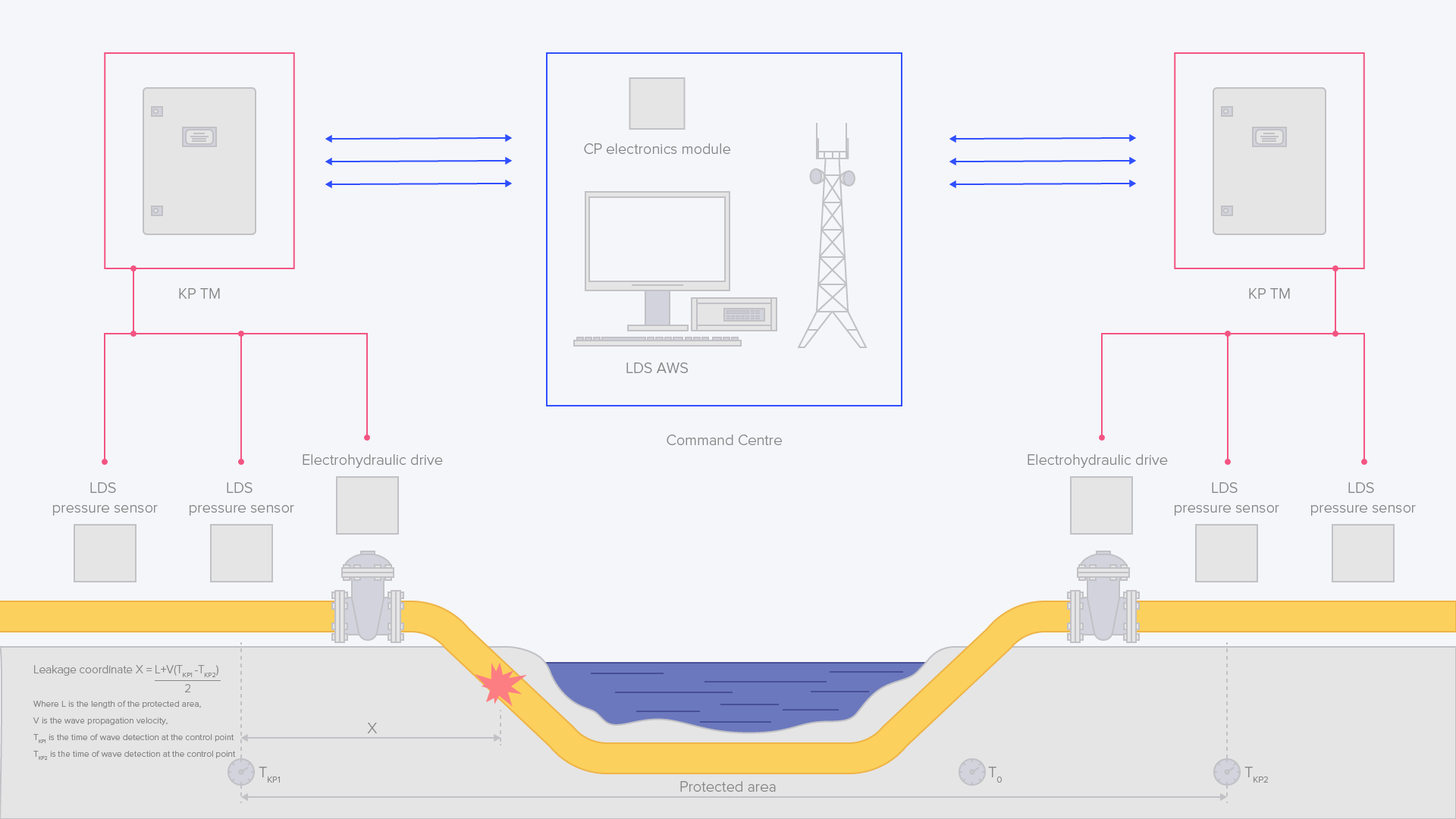

The oil pipeline leak detection system (LDS) provides for quick detection of leakage and determines where and when it occurred. Timely detection can significantly reduce the reaction time of emergency services and, as a result, significantly reduce the environmental damage from spillage.

The leak detection system is a software and hardware package that processes information from sensors located on the pipeline in real time to detect leakage as well as pinpointing its time and location.

The system uses several leak detection methods:

- pressure wave analysis

- volumetric balance analysis

- pressure profile analysis

Pressure wave analysis is used for the quick identification of small leaks with high precision.

The concept behind this method is to analyze the propagation of waves of pressure drop in the pipeline. To monitor the pressure waves, the supervised telemechanics station is equipped with two LDS pressure sensors that are connected to the leak detection unit.

The unit analyzes the signals from the sensors, detects the pressure drop waves and determines their direction and transit time. Using a GPS receiver for synchronization makes it possible to record the moment of passage of the wave with great precision. Information about detected waves is delivered to the control point via the telemechanics system. Based on the nature of the wave propagation in the pipeline, the LDS server analyzes the information received and determines that there is a leak, the time of its occurrence, and its exact coordinates.

Volumetric balance analysis and pressure profile analysis are parametric methods. They use information from flow and pressure sensors located on the pipeline and do not require the installation of any additional equipment. These methods make it possible to detect the occurrence and location of medium to large leaks based on analysis of the change in certain technological parameters.

Fields of application

- Condensate pipelines

- Gas pipelines

- Oil pipelines

Signature features:

Extremely low power consumption

The leak detection units are designed for operation in non-volatile systems and have extremely low power consumption

Operation in extreme climates

The GPS receiver used in conjunction with the leak detection unit is designed to operate even in the extreme conditions of the Far North

Increased reliability and elimination of "false" leak detections

The LDS incorporates a special algorithm for confirmation of a leak before triggering an alarm, resulting in increased reliability and the elimination of "false" leak detections

Can be integrated into the linear telemechanics system

The LDS can be integrated into the pipeline’s linear telemechanics system. It is not necessary to set up separate communication channels for data transmission

Collection of measurement data regarding technological parameters

The system provides for the collection and transmission of technological parameter measurement data

Flexible unit placement

Individual units of the Leak Detection System are designed to allow their placement either separately or as expansion modules in telemechanic system controllers

Special software

The LDS includes special software for modeling the operation of the system using given parameters based on historical data

Characteristics

The minimum detectable leakage by pressure wave analysis

5m3/hour.

Error in determination of coordinates by pressure wave analysis

±0.1 km.

Time of leakage detection by pressure wave analysis

1.5 min.

The minimum detectable leakage using parametric method analysis

10m3/hour

Error in determination of coordinates using parametric methods

±2 km.

Time of leakage detection using parametric methods

15 min.

show all Characteristics

How the LDS works

Product order

Contact us

HyperFlow-ASSD

Automated data collection system

Your cart