Telemechanics

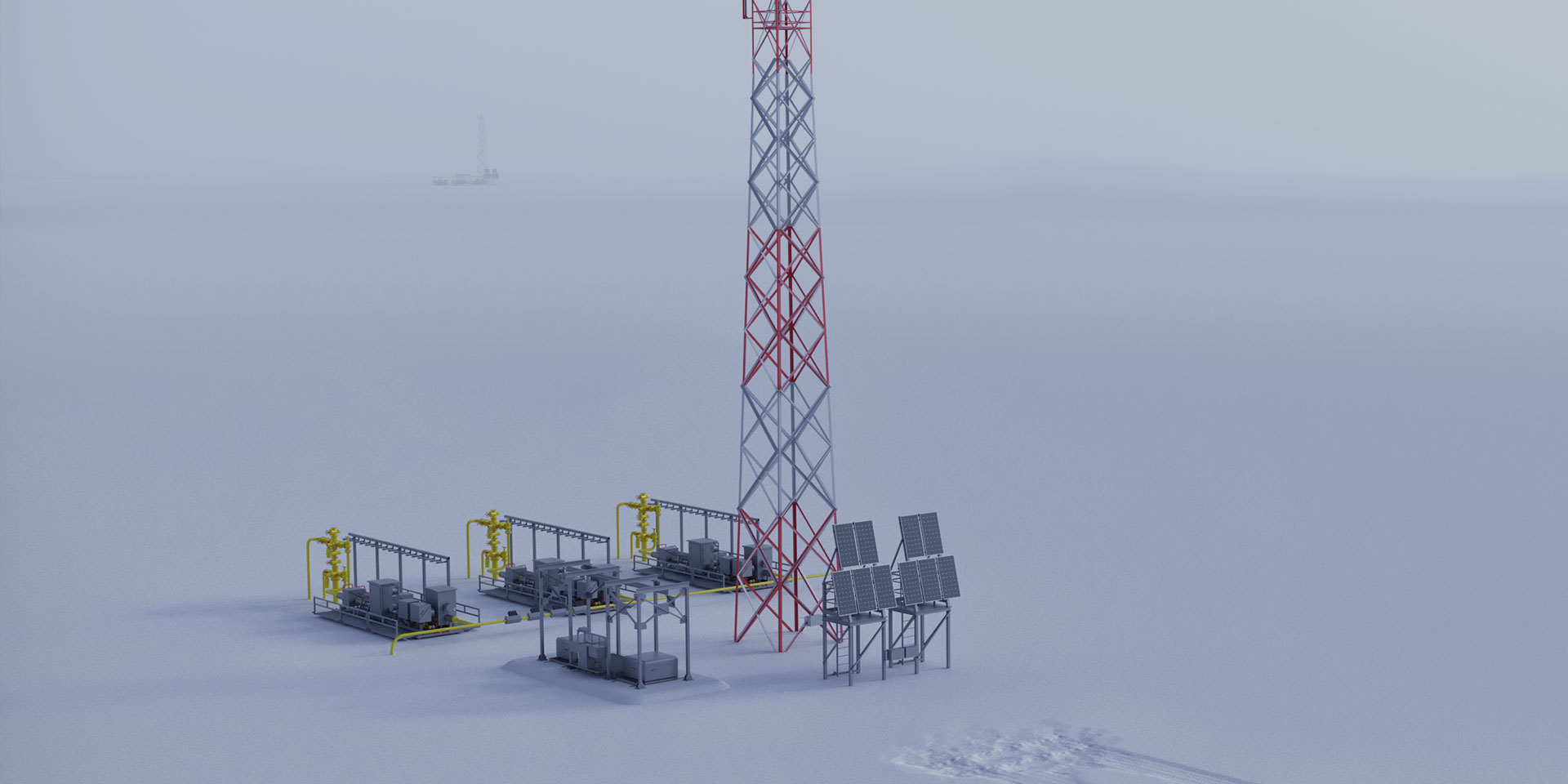

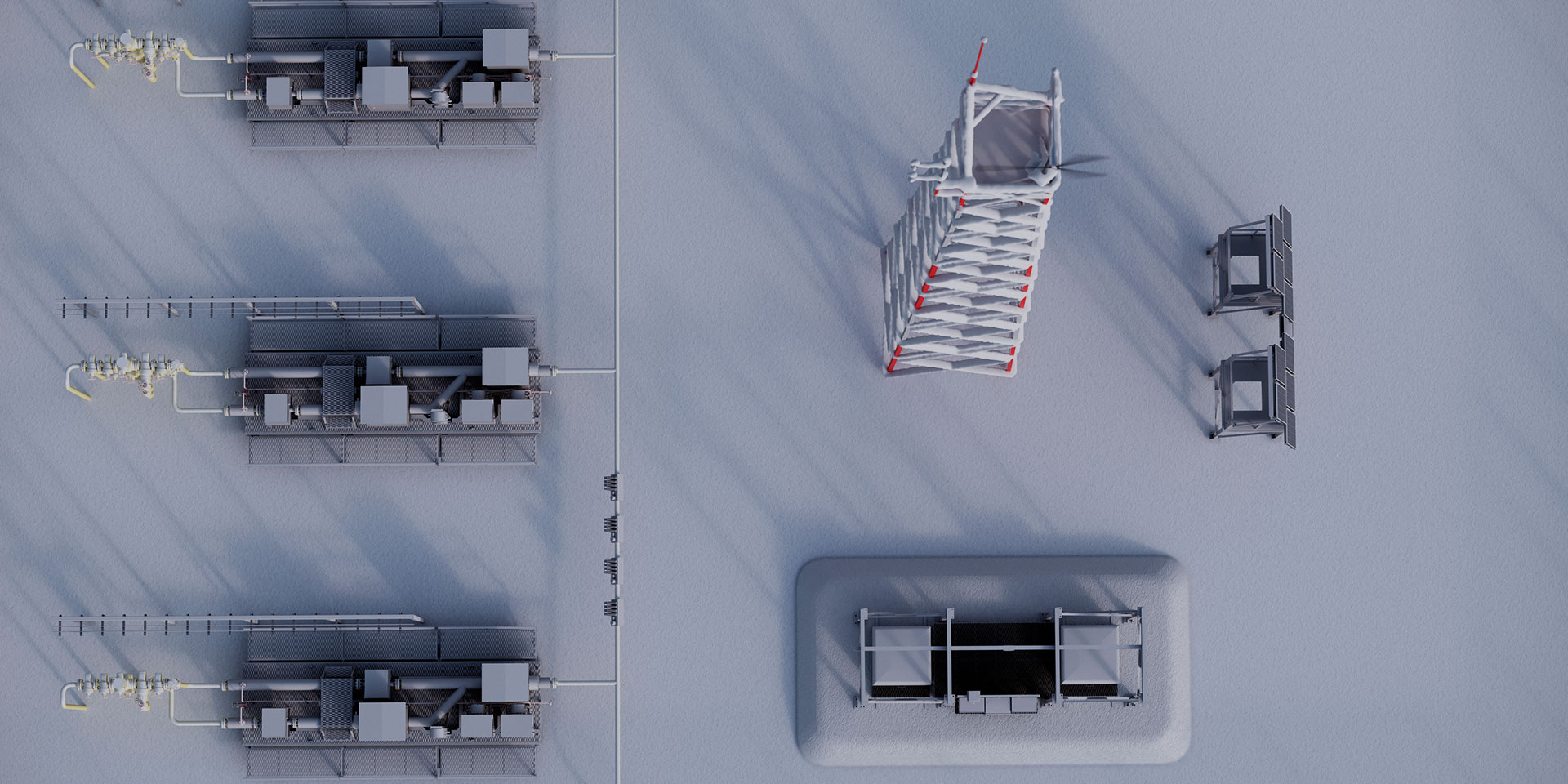

Telemechanics complex for gas well clusters

Telemechanics complex

for gas well clusters

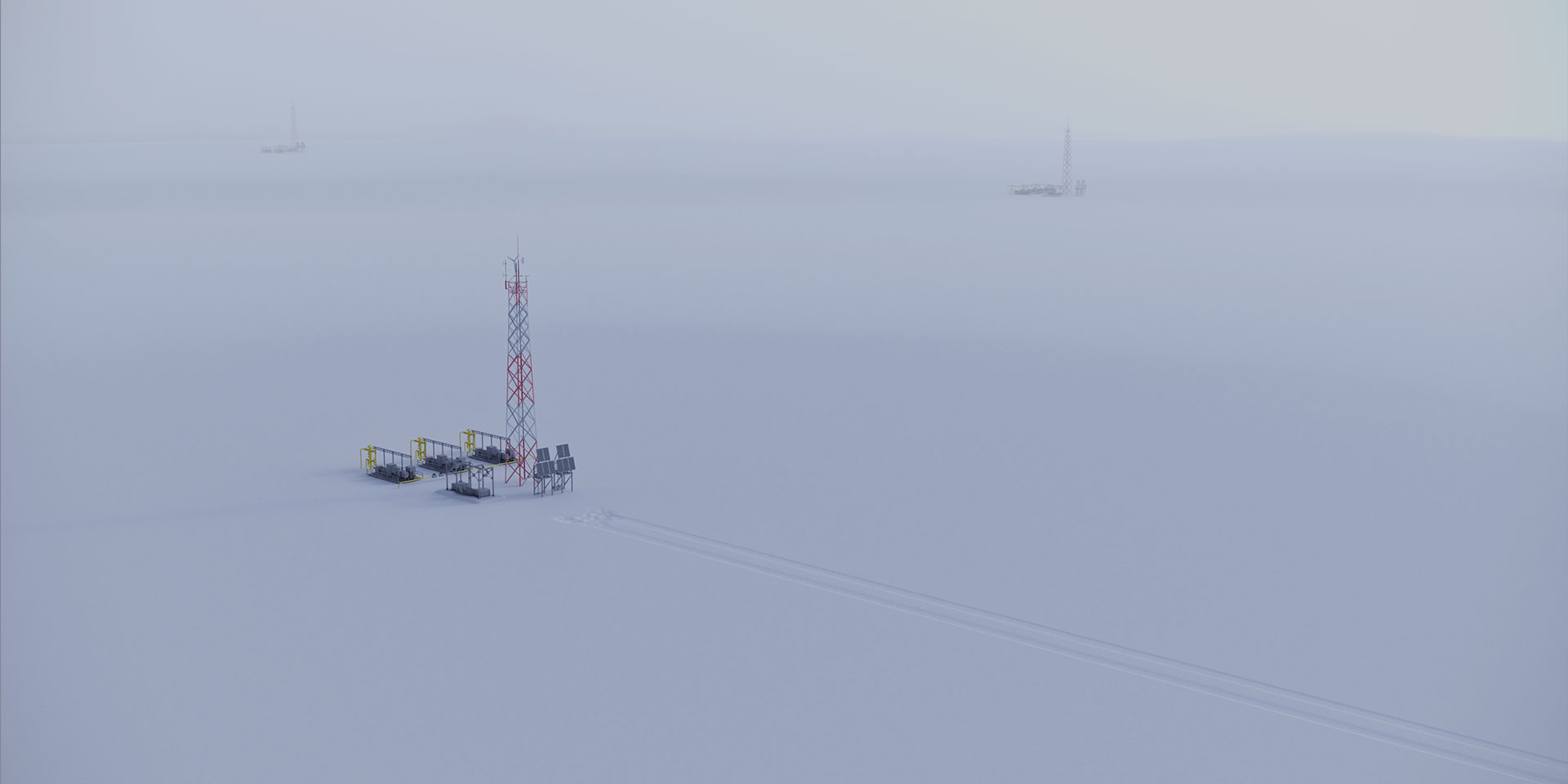

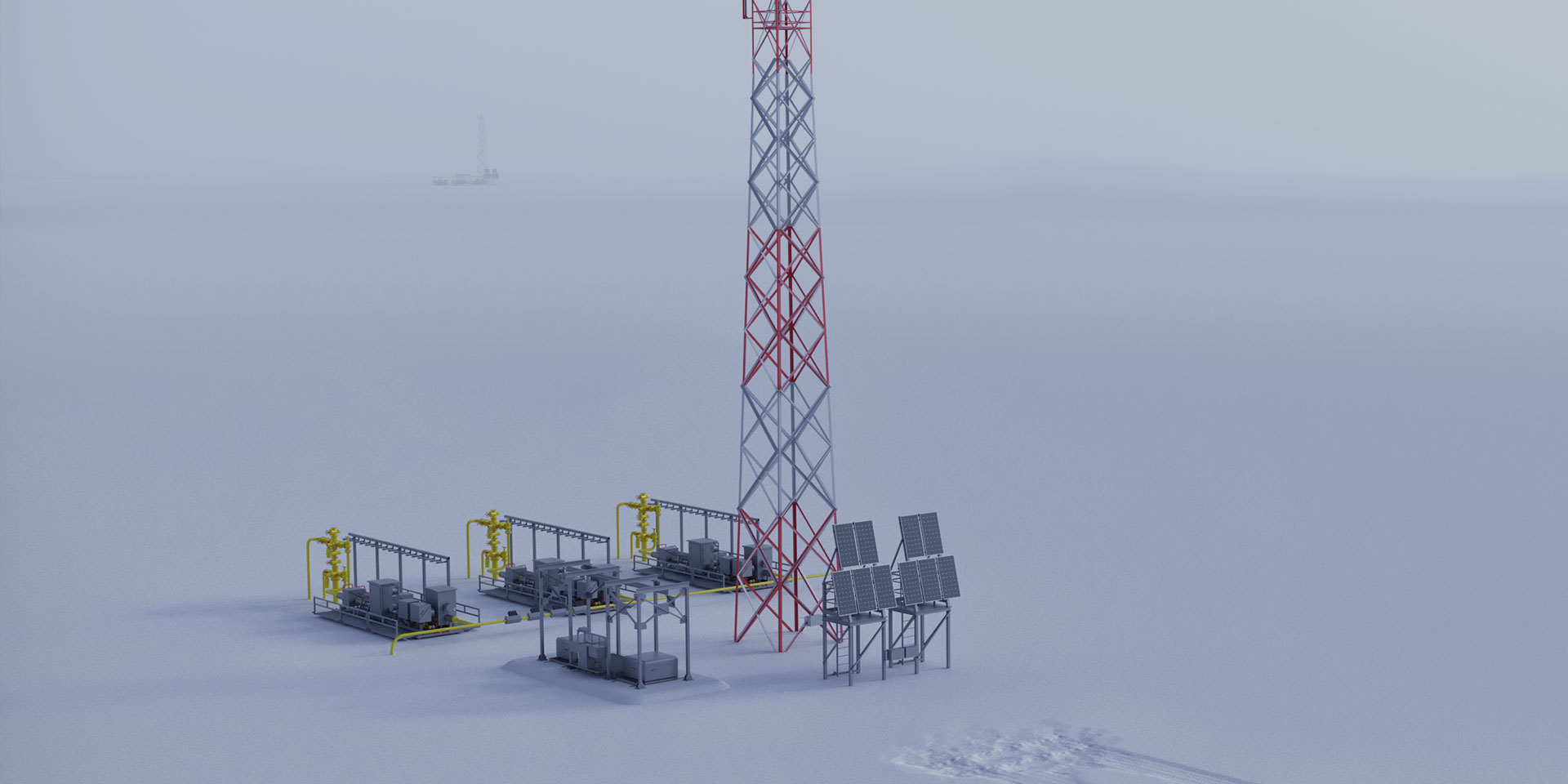

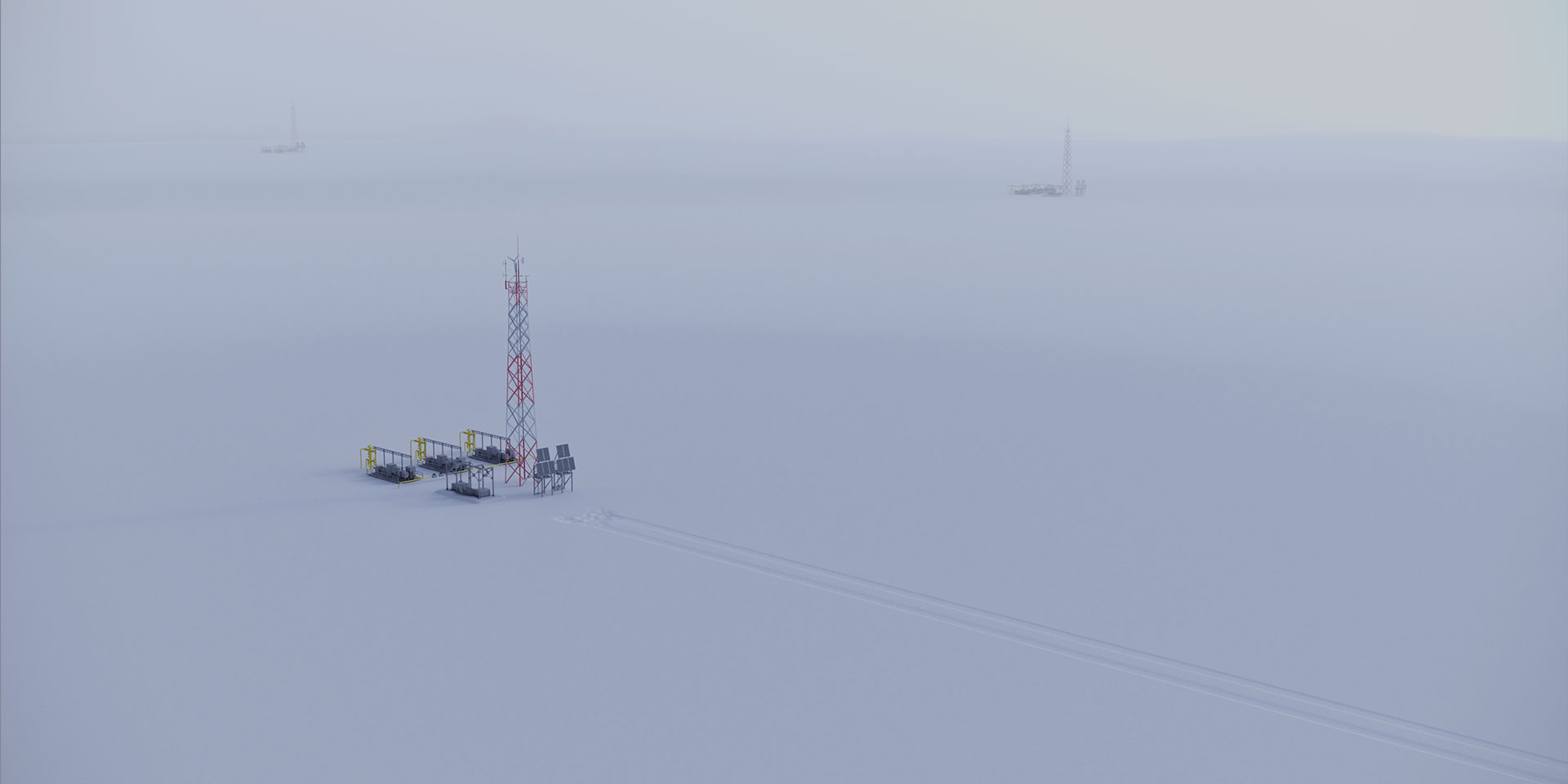

The Telemechanics complex for gas-condensate well clusters (GWC TMS) is a system designed for the centralized automated control and operational management of gas condensate wells.

The incorporation of innovations developed by SPA Vympel in-house makes it possible to install the complex at both electrified and non-electrified industrial sites.

Using the complex at non-electrified sites is possible thanks to the ultra-low energy consumption of all system components, which were developed by SPA Vympel.

The climate protection measures, which were also developed and tested by SPA Vympel, ensure the normal functioning of the complex in severe climatic conditions – including in the Far North and without additional heating.

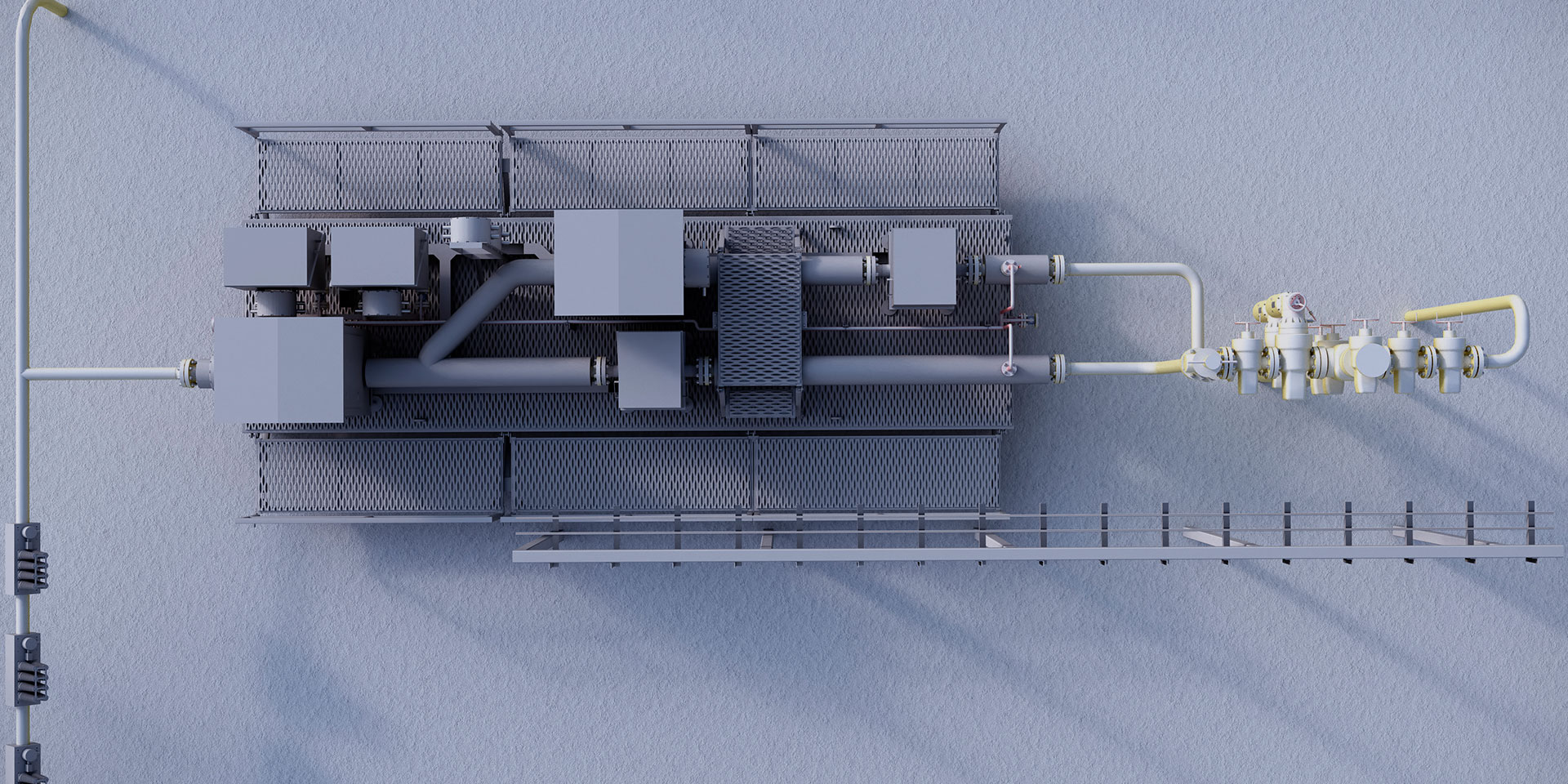

Main functions:

- Centralized automated control of gas wells operation;

- Automatic collection and transmission of data received from flow metering units installed on the well pipelines;

- Flow rate control and supply of a hydrate inhibitor at a predetermined rate;

- Implementation of specific complex algorithms (technological tasks and emergency shutdown);

- Control of pipeline shut-off valves of the pipeline, a Christmas tree and a wellhead valve;

- Control of the cathodic protection system (CPS);

- Self-powered operation thanks to the incorporation of several DC power sources into the system;

- Digital communication between the cluster set (CS) and the dispatch set (DS) of the GWC TMS via radio communication;

- Integration of the GWC TMS into the gas production technological preparation automated control system (GPTPACS).

Fields of Application

- Gas condensate fields

- Underground gas storage facilities

Signature

features

Centralized automated control of gas well operation

Automatic collection and transfer of information

Automatic collection and transfer of data received on flow metering units installed on the well pipelines;

Implementation of complex algorithms

The system implements complex algorithms for managing the technological process of natural gas production, including the regulation of the flow rate of each well, as well as the algorithms for emergency shutdown.

Flow rate control and supply of a predetermined rate of hydrate inhibitor

Operation using self-generated power supply

Self-powered operation thanks to the incorporation of several DC power sources into the system;

Characteristics

Ambient temperature

-60°C to +50°C

Ambient humidity

up to 98% at a temperature of 30°C

Annual period during which access to gas wells is difficult

9 months a year

Operating pressure of the measured medium

up to 250 kg/cm2

Measured medium temperature

-30°C to +40°C

show all Characteristics

Principle of operation:

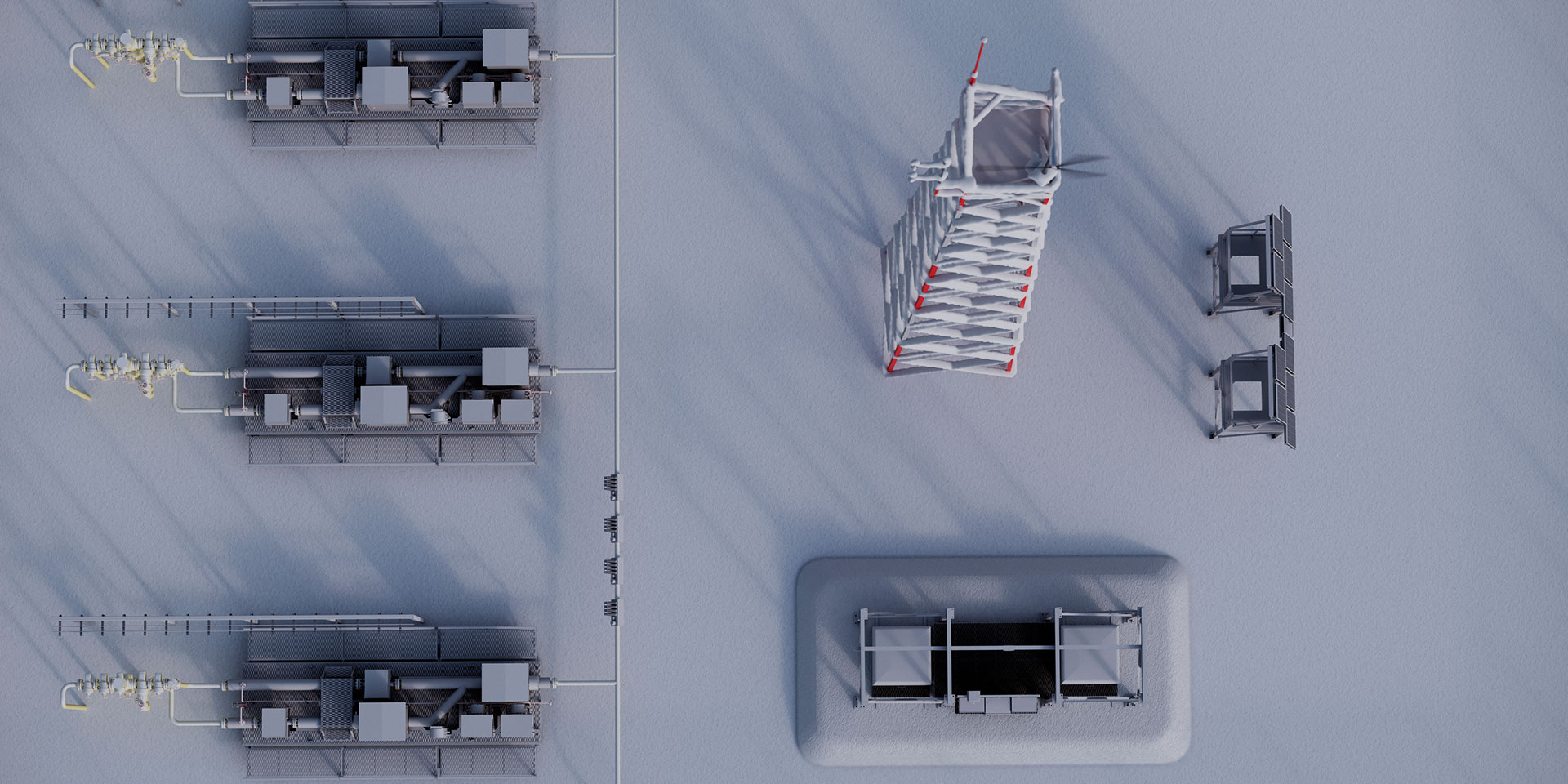

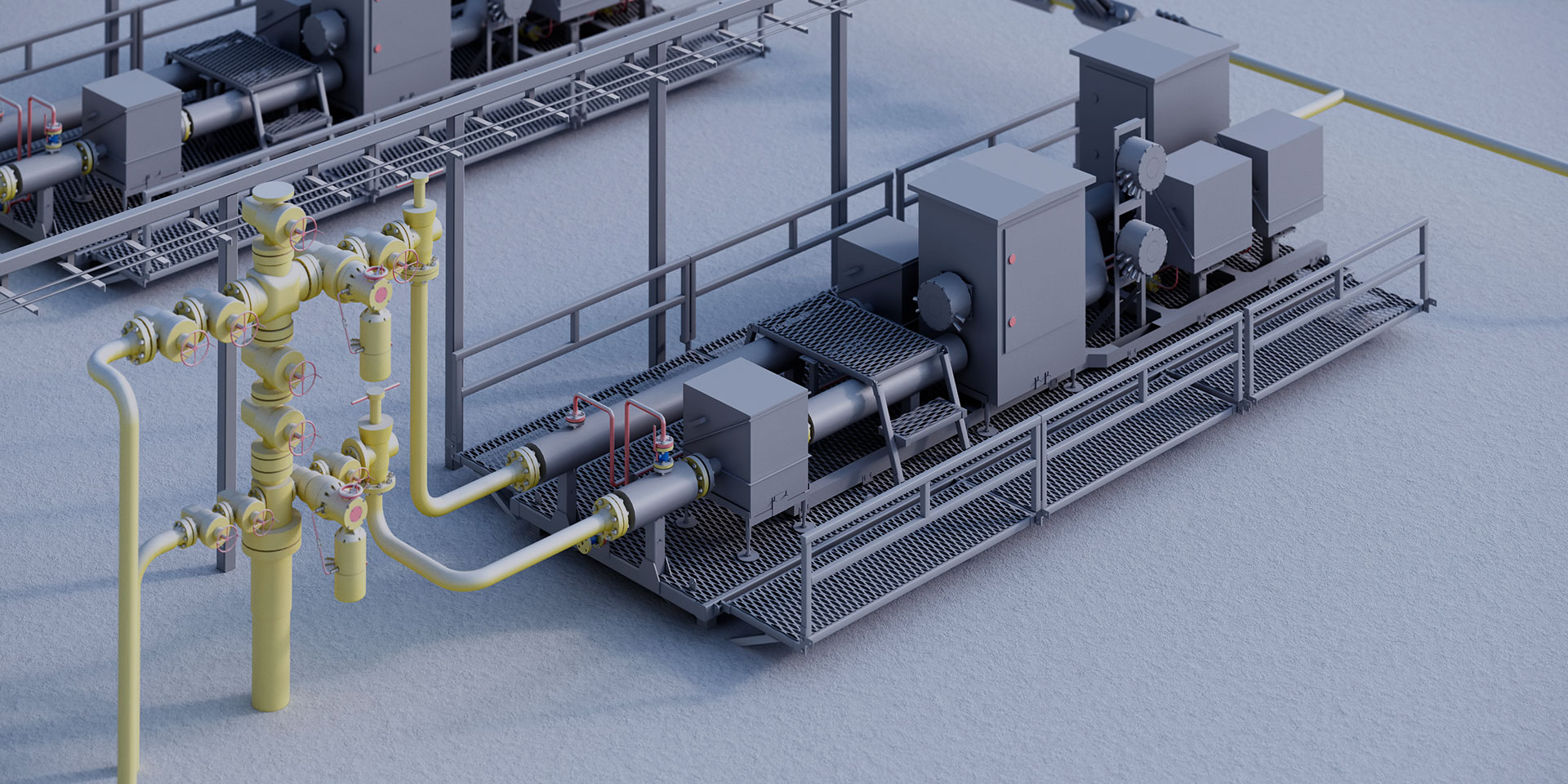

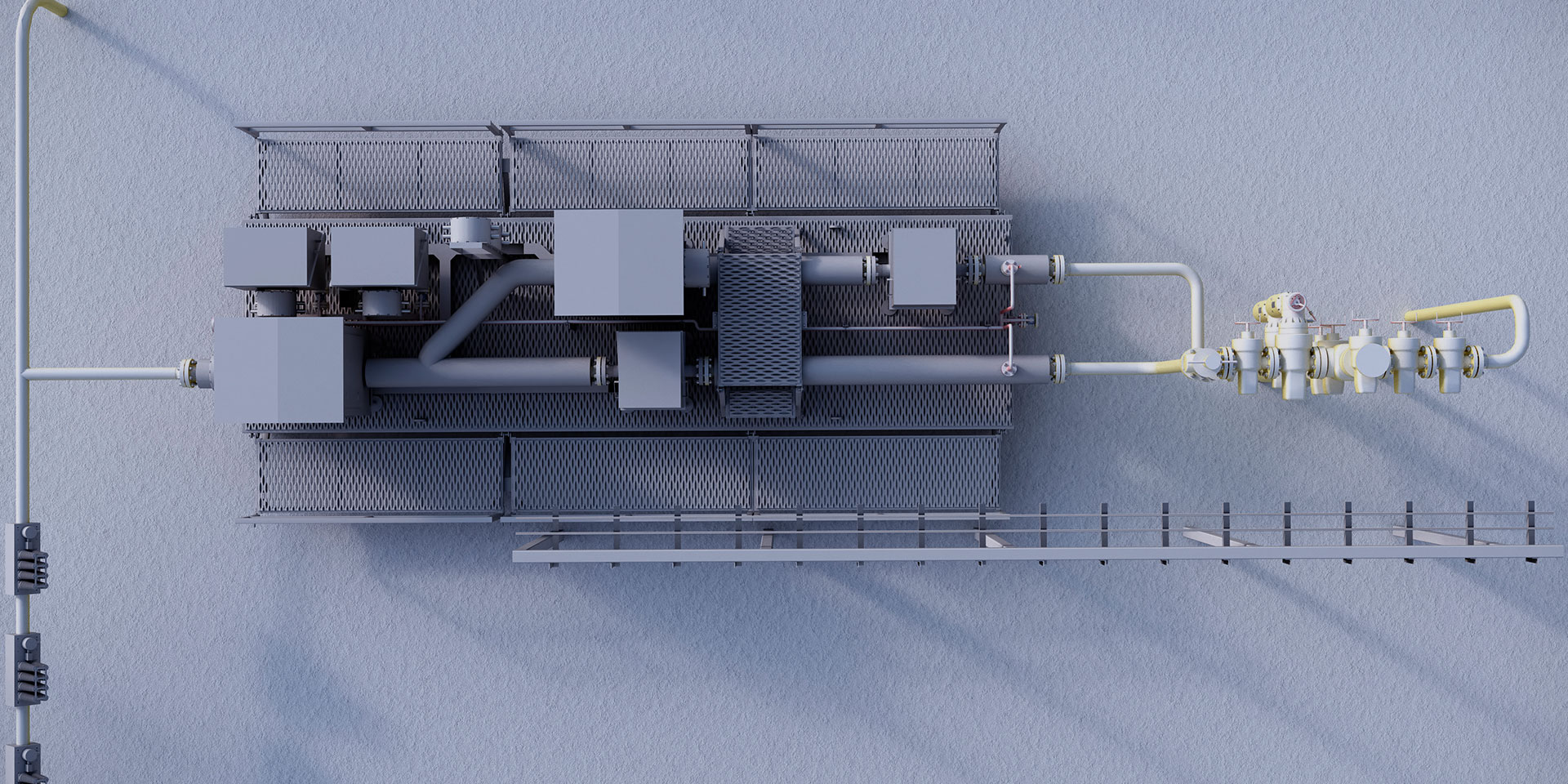

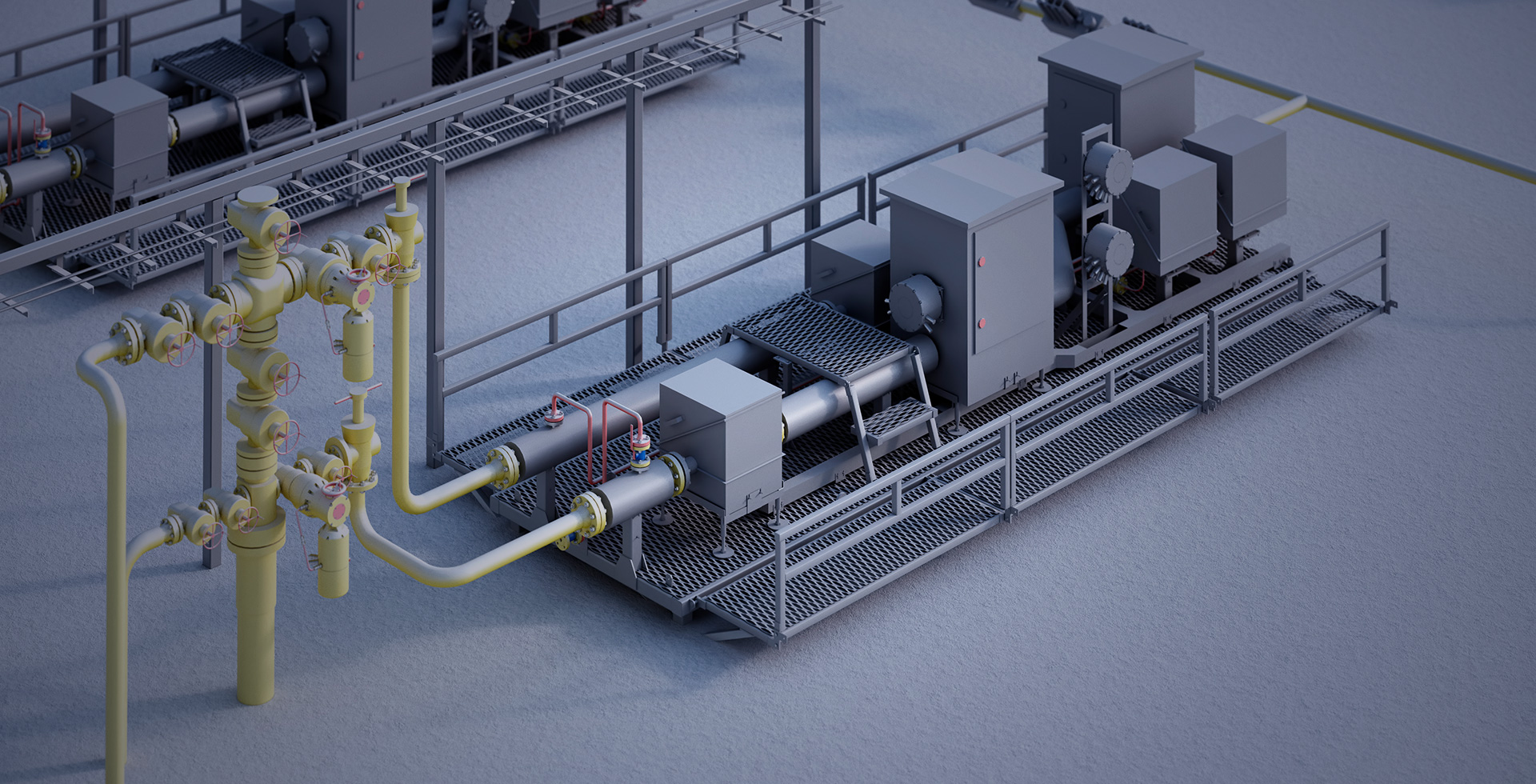

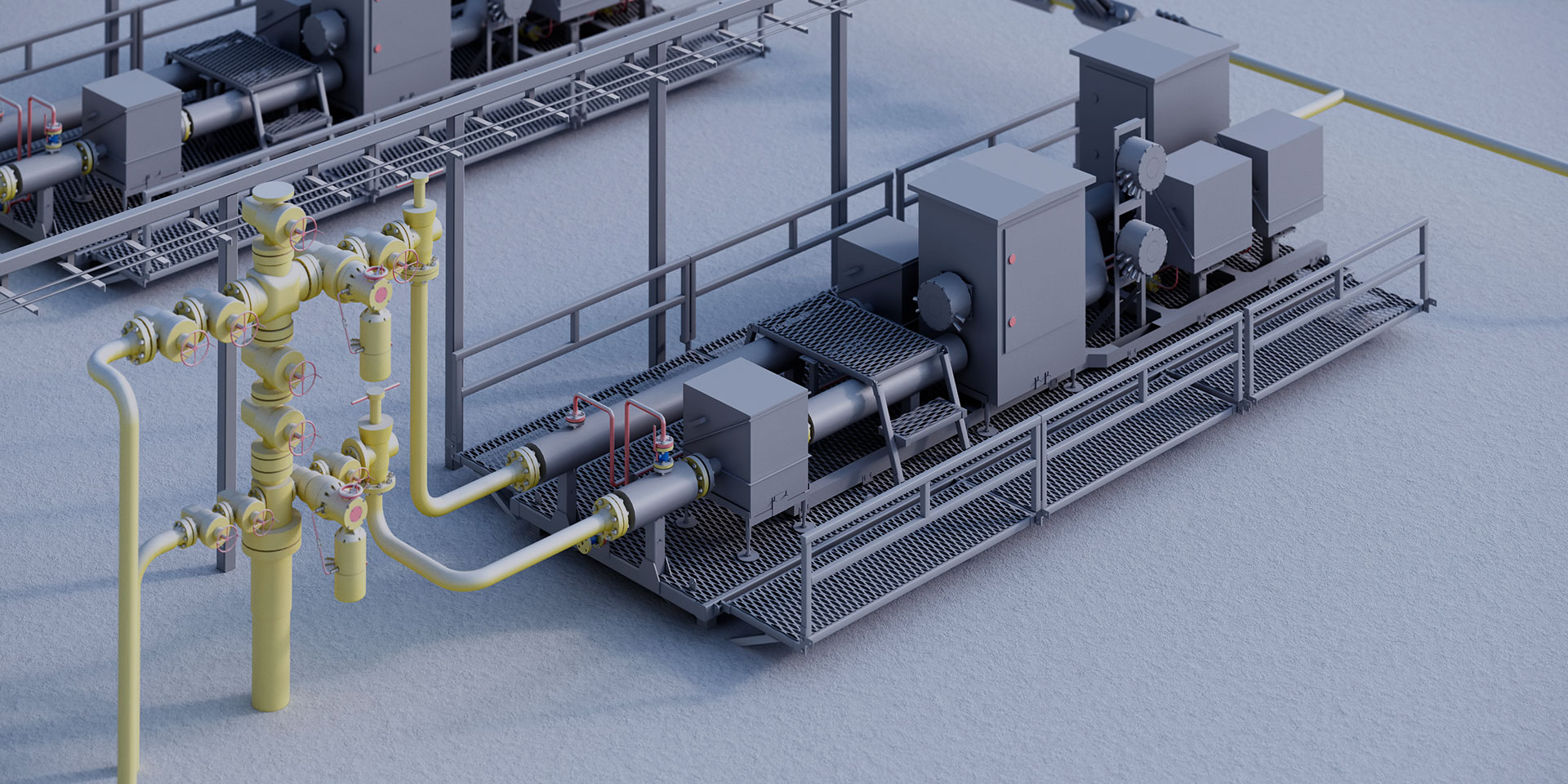

The GWC TMS is a centralized system for the gathering, processing, presentation, storage, and transfer to upper level systems of information about the parameters and conditions of well operation, measurement instrument diagnostics, and power supply system status. In addition, the GWC TMS includes a system for the remote control of the gas well flow rate and control of the supply of hydrate inhibitor injected into the system.

The GWC TMS is a two-level system:

- the first level - the telemechanics cluster level

- second level - the system control level.

GWC TMS controlled point features include:

- Collation of data obtained from instrumentation and control devices installed on the gas well’s pipelines and manifold

- Control of the cathodic protection system (CPS)

- transfer of data via radio signal to a network level control point (CP)

- alarms for unauthorized access

- maintenance of its own operational capacity by regulation of the power supply parameters and the air temperature in the enclosure

The cabinet controllers of the controlled point read the data stored in the instruments’ memories as well as the data from actuators and transfer this information via wireless connection to the GWC TMS CP electronics module. These operations are done in accordance with the survey grid and at the shortest possible intervals.

Collected data is displayed on the screen of the engineer's AWS terminal, and is archived. It can also be transferred to the top-level IMS.

Configuration*

show package contents

Main set

Control point. Telemechanics dispatch package for gas well clusters

Dispatching kit electronics module

Operator workstation

HP Printer

Uninterrupted power supply

AWS application software

The system software as well as special software for the Complex, the configuration, and programming tools

I-Fix software package with licenses for workstations

Engineer AWS

Uninterrupted power supply

The system and special software for the Complex, configuration and programming tools

I-Fix software package with licenses for the engineering station

Application software for Motorola ACE3640 controllers

A set of antenna-feeder devices

Telemechanics controlled point for gas well clusters

Telemechanics cabinet

Backup power supply

Instrumentation

HyperFlow gas flow meter

4-20 mA pressure sensor

Surface resistive temperature transducer

Actuators

SPI-02 inhibitor supply system

Gas well flow rate regulator

Regulating valve with electric drive

Power supply devices

Backup power supply

Service equipment and spare parts

* may be altered. Clarified at the time of order

show package contents

Product order

Contact us

Declining production stimulation

using concentric tubing

Gas well operation centralized automatic control

Automatic collection and transfer of information

Automatic collection and transfer of data received on flow metering units installed on the well pipelines;

Implementation of complex algorithms

The system implements complex algorithms for managing the technological process of natural gas production, including the regulation of the flow rate of each well, as well as the algorithms for emergency shutdown.

Flow rate control and supply of a predetermined rate of hydrate inhibitor

Power supply for own operation

Powering own operation due to use of several DC sources included into its composition;

Используйте клавиатуру

Your cart