Chilled Out

The 21st Century has already witnessed some significant developments in the natural gas industry, such as the emergence of LNG as a major factor in global gas distribution, the increased interconnection of natural gas transport networks, and the imposition of increasingly stringent quality control standards, to name just a few. These recent developments mean that gas quality control measurements are more important than ever. However, these same developments have led to an increasing number of situations in which the gas to be measured is extremely dry, which presents a challenge.

The best method for any required measurement is based on first principles. Outside of a laboratory setting, the most suitable first principle method for accurate and repeatable measurement of the humidity or water content in natural gas is by means of a chilled-mirror hygrometer. The challenge presented by recent developments is chilling the mirror to a temperature that is low enough in order to directly measure the dew point of extremely dry gas.

Most automatic online devices are simply not capable of achieving the necessary degree of temperature depression. One or two analysers are able to employ supplemental cooling to successfully measure at these lower temperatures, but this adds cost and complexity to the system.

This article will introduce a new analyser that features increased cooling performance without the need for supplemental cooling. In order to appreciate the implications of this achievement, it may be worth taking a closer look at chilled-mirror technology in general.

Chilled-mirror technology

Anyone who has ever enjoyed a glass of an ice-cold beverage on a hot summer day is familiar with the process that is at the heart of a chilled-mirror hygrometer. The droplets of water condensation that form on the outside of the glass are a manifestation of exactly the same process that occurs when a gas sample is exposed to the surface of the temperature-controlled mirror inside the hygrometer.

The formation of water condensation on a cold surface is influenced by three factors: pressure, temperature and humidity. For a given sample of air or natural gas, assuming the pressure is stable, the warmer the temperature, the more water vapour the air can hold. At the temperature where the air is unable to hold any more water vapour, the air is said to be saturated. The saturation temperature is also known as the dew point. A given dew point temperature at a given pressure correlates directly to a given amount of moisture in the gas. Therefore, by measuring the dew point one is also measuring the water content.

Humidity

On that hot summer day, the humidity can be high. When the air comes into contact with the cold glass, the layer of air adjacent to the glass is cooled. As the temperature of this layer decreases, the amount of water it can hold also decreases. This forces the excess water vapour to condense onto the surface of the glass, forming those familiar droplets.

A similar situation is happening in a chilled-mirror hygrometer. The sample gas is exposed to a surface that is slowly chilled to a level below the saturation temperature. As a result, the water vapour that is present condenses out of a gaseous state. In this case, however, the conditions are controlled and the temperature of the surface is carefully modulated and monitored. In this way, the specific temperature at which condensation first occurs can be established. Here, again, the term for this temperature is the dew point.

Gas that is too wet can result in a number of problems, so gas humidity is carefully regulated, either by law, by contract or both. Penalties for failure to meet these standards can be significant, so accurate, reliable measurements are necessary.

Condensation is determined by the inherent properties of the gas, so direct measurement is considered to be a first principles measurement. This type of measurement is considered preferable to methods that require calculation to arrive at the dew point. Moreover, measurements made using a chilled-mirror hygrometer are reliable and repeatable.

It took several years to develop a reliable method for measuring the humidity of natural gas, and longer still to develop reliable automated measuring devices. A variety of different types of hygrometer were tried, but all of these devices had been developed for measuring atmospheric humidity and most were unsuitable for natural gas applications.

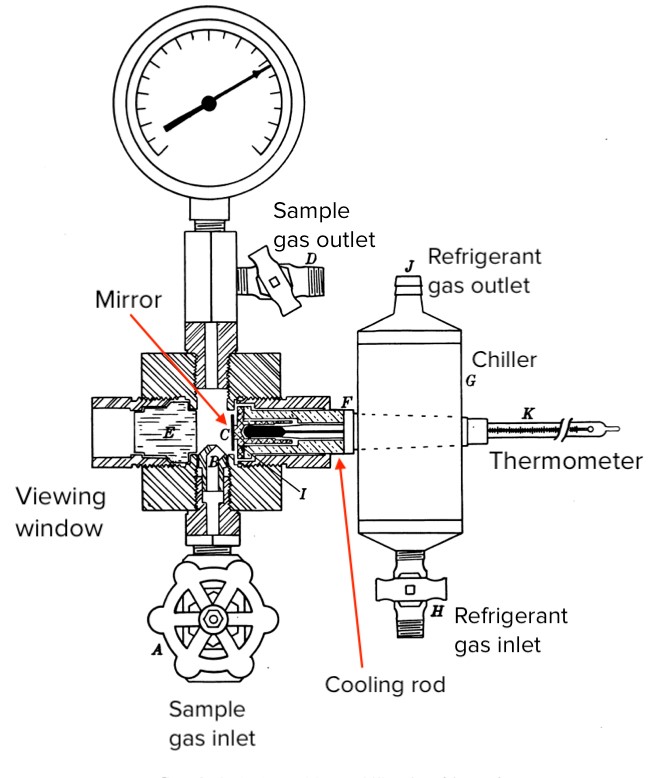

Fortunately, the chilled-mirror hygrometer could be made robust enough to withstand the specific challenges of measuring the dew point of natural gas under pressure. The Bureau of Mines dew point apparatus, often called the ‘Bureau of Mines type dew point tester’, was the first device to fulfil all of the necessary requirements for “(1) precision or reproducibility of determinations, (2) accuracy (3) safety, and (4) suitability for use with natural gas under pressure.”1 This device from 1938, shown in Figure 1, is virtually unchanged, as presented in the current ASTM D 1142 standard, where it is described and illustrated as the recognised example of a device that conforms with the ‘Standard Test Method for Water Vapor Content of Gaseous Fuels by Measurement of Dew-Point Temperature’.2, 3

Figure 1. Bureau of Mines type Tester

Cooling

Of course, at the heart of any chilled-mirror device is the cooling component. In the Bureau of Mines device, this component is an amalgam of several elements, including a refrigerant gas, a ‘chiller’, a copper cooling rod soldered to the polished stainless-steel mirror, and a bulb thermometer located in a well in the cooling rod. By stopping the flow of the refrigerant gas, the cooling rod warms up again in response to the ambient temperature.

While this system is effective at actively cooling the mirror, warming the mirror is limited to passively allowing the temperature to rise again. This limits the operator’s ability to control the mirror’s temperature. In addition, the device is a manually operated device that requires a skilled and experienced operator to produce satisfactory results.

Measurement

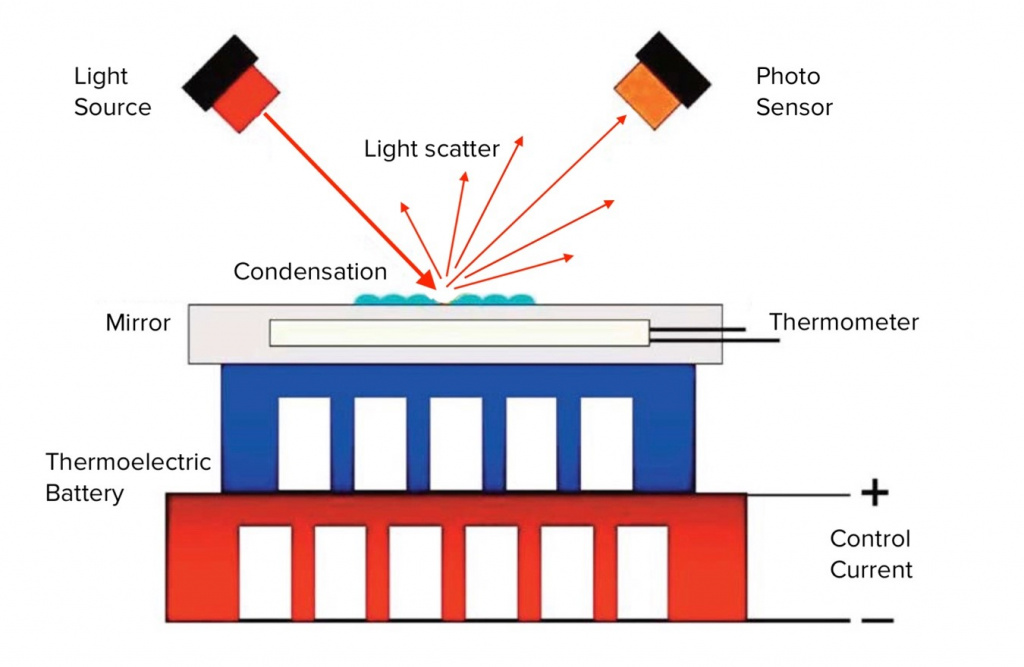

In order to automate the process of measuring the dew point, a method to heat the mirror in a controlled way is required. A Peltier element (also known as a thermoelectric battery) uses the thermoelectric effect to produce both cooling and heating. This effect is the result of passing a direct current (DC) through the junction of two dissimilar conductive materials. Whether the device heats or cools is dependent on the direction of the flow of the current. These devices can be configured into multi-stage coolers that achieve significant temperature gradients.

Similarly, a thermocouple is used instead of a bulb thermometer in a modern automatic hygrometer. A thermocouple consists of two dissimilar conductive materials, usually metal, that are connected to form an electrical junction. When this junction is exposed to a temperature change, a voltage is created. Based on this electrical current, it is possible to calculate the temperature.

An automated hygrometer is comprised of a thermoelectric battery, a thermocouple (thermometer), a light source, a condensation mirror, and a photo sensor. The basic layout is shown in Figure 2.

Figure 2. Basic layout of an automatic chilled-mirror hygrometer

The performance of a thermoelectric battery is subject to the limitations of the materials from which it is made. In addition, the thermal exchange between the thermoelectric battery and the mirror is limited by the conductive efficiency of the components and the way in which they are joined. Traditionally, a measurement range from -30 to 30°C has been the standard. This correlates well to the temperature depression of 60°C below the ambient temperature that is achievable by most analysers.

However, operators increasingly require specific information about moisture levels that correspond to much lower dew point temperatures. As a result, alternative technologies that are not limited by the performance of a thermoelectric battery are being marketed. In particular, capacitance-type sensors (often based on aluminium oxide or ‘alox’), tuned diode laser absorption spectroscopy (TDLAS) analysers, and quartz crystal microbalance (QCM) devices have been developed to measure dew point at temperatures of -80°C or below.

While capacitance sensors are inexpensive, they can drift, and lower temperatures only exaggerate this phenomenon. These devices require regular recalibration, which means removal and system down time. TDLAS analysers do not drift, but they are often sensitive to fluctuations in gas composition. Recalibration for new conditions can be expensive and time-consuming. In addition, measurements using TDLAS technology must be made at pressures at or below 1 bar, far from the actual conditions of the pipeline gas. QCM devices operate on the principle of addition or subtraction of water molecules to a quartz crystal resonator. This type of device requires recalibration every two to three measurement cycles, so a recalibration system is built into QCM devices. Such a system requires a reference gas stream, so a bottle of calibration gas is also necessary. The complexity of the system and the requirement for consumables add expense to QCM analysers.

These devices are more suited to reporting the presence of water in terms of ppmv or ppbv, and they do not take first principle measurements or measure the dew point. This, in itself, is not a problem. However, where dew point values are required, a calculated conversion is necessary.

Is there a better solution?

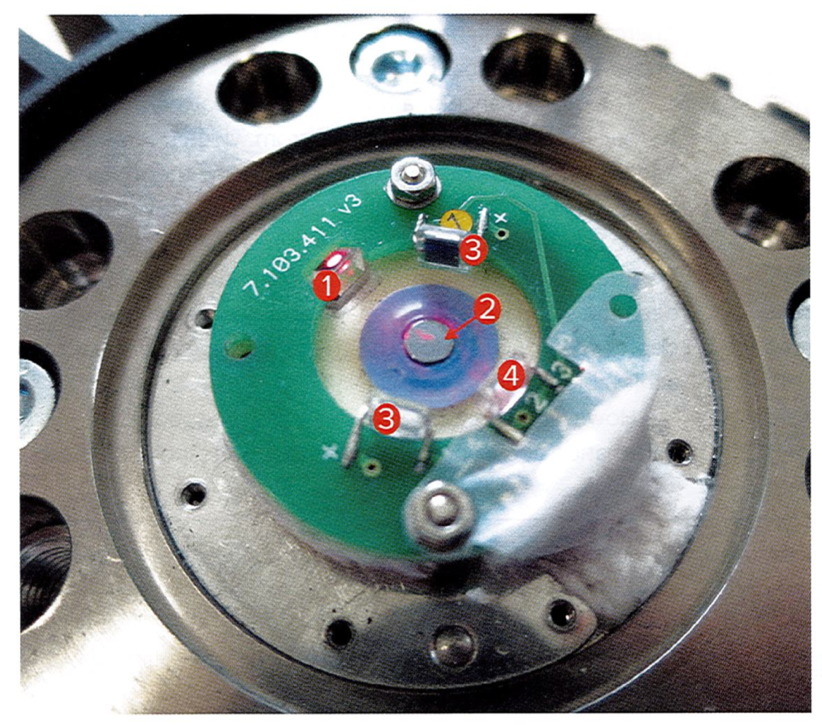

Vympel has designed a new chilled-mirror analyser, the FAS-W. Constrained by the limits inherent in the architecture of any chilled-mirror hygrometer as well as the requirements imposed by proprietary technologies, Vympel engineers based their new device on the same technology used in earlier dew point analysers, such as the CONG Prima 2M. But for the FAS-W they took advantage of newly developed materials and methods, to deliver a performance level that was previously unattainable. For example, the mirror has been made 60% smaller, which reduces the amount of energy required to achieve the same level of cooling. In addition, thermal isolation of the mirror/thermoelectric battery composite was upgraded, which achieved a significant improvement in cooling efficiency, and the thermoelectric battery was improved to deliver higher baseline performance. An image of the inner layout of the FAS-W measurement cell is shown in Figure 3.

Figure 3. Interior of the FAS-W measurement cell:

Whereas the previous standard measurement range was -30 – 30 °C, the new chilled-mirror analyser has a range of -80 – 65 °C. In addition, the mirror is heated to a temperature of 80°C between measurement cycles, to ensure that any condensation (water or hydrocarbons) will be evaporated from the mirror. Previously this temperature had an upper limit of approximately 60°C.

The engineers also upgraded the electronics and outfitted the analyser with a dedicated port for inputting pressure data, so that water content can be reported in terms of ppmv or mg/m3.

Of course, as is the case with the development of any new device, trade-offs were necessary. In the case of the new analyser, a slight reduction in accuracy was deemed acceptable in order to achieve the improvements in cooling performance without adding unacceptable expense.

Customers should now be able to look forward to a new generation of chilled-mirror analysers that are designed to meet the ever more demanding requirements of the global natural gas industry.

Conclusion

While natural gas is a cleaner source of energy than coal or oil, still more ecologically friendly alternatives are predicted to emerge in the future. One of these is hydrogen. In the coming decades, the next frontier for dew point analysis may well be to measure the moisture content of hydrogen flowing through what used to be natural gas pipelines. Since chilled-mirror hygrometers provide a first-principle measurement, it is likely that this type of device will continue to continue to play a key role in monitoring moisture content. There is no reason to doubt that the engineers and designers responsible for future technological developments will continue to deliver new solutions to meet new challenges.

References:

1. DEATON, W. M. and FROST, E. M., Jr, 'Bureau of Mines Apparatus for Determining the Dew Point of Gases Under Pressure', Bureau of Mines Report of Investigation 3399, (May 1938).

2. DEREVYAGIN, A. M., SELEZNEV, S. V., STEPANOV, A. R., AGALTSOV, A.G. and ISTOMIN, V. A., 'A New Approach for Measuring Water

and Heavy Hydrocarbon Dew Points of Natural Gases by using a Three-channel Laser Interferometer', Materials of the 23rd World Gas Conference, Amsterdam, the Netherlands, (2006), Report No. 99.16.

3. ASTM D1142-95, 'Standard Test Method for Water Vapor Content of Gaseous Fuels by Measurement of Dew-Point Temperature', ASTM International, West Conshohocken, Pennsylvania, US, (2012).